GRP/FRP Water Tank Solutions

TechnoFRP: Your Local Partner for High-Quality GRP and FRP Water Tank Panel Solutions

With over 20 years of experience in the composite industry, TechnoFRP has been a trusted local provider of GRP and FRP water tank panels. We offer a comprehensive range of solutions—from raw materials and molding machines to the final product. Whether you're looking for a custom-made solution or the full production line, we can meet your specific needs with professional expertise and local support.

Our services include:

- SMC Raw Materials: The best materials for durable and reliable water tank panels.

- Sheet Machines: Precision equipment for efficient production.

- SMC Molds & Hydraulic Presses: Tailored to your specifications, ensuring perfect molding every time.

- Drilling Machines: For precise finishing and quality control.

Additionally, we supply finished water tank panels, ensuring you receive a complete solution from start to finish. As a local partner, we’re here to solve your production and manufacturing challenges with solutions that are tailored specifically to your business.

Let us help you build the best water tanks with solutions designed to fit your unique needs.

(SMC) Sheet Molding Compound is a pre-impregnated thermosetting plastic, molded under high temperature and pressure, which eliminates styrene emissions, and has uniform strength and a smooth surface. Its main raw materials are GF (special yarn), UP (unsaturated resin), low shrinkage additives, MD (filler), and various additives. It has excellent electrical insulation properties, mechanical properties, thermal stability, chemical resistance, and corrosion resistance, and is mainly used to produce GRP water tank panels, septic tank panels, GRP exhaust pipes, etc.

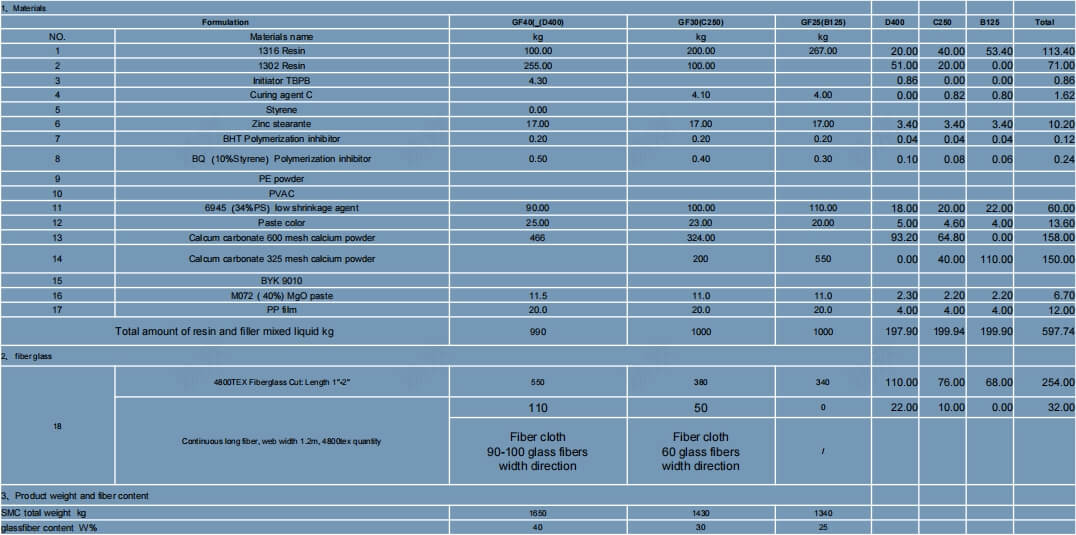

TechnoFRP's SMC material is made of SMC chopped strands with a length of 2.5mm, with a content of 15%, 20%, 25%, or 30%. Mixed with polyester resin and flame retardant, then pressed into 1m wide material and sealed in PVC film bags. We can provide SMC material formulas for our customers.

SMC sheet production equipment is divided into two parts. One is the resin paste preparation equipment, which generally uses a vertical high-speed disperser. The other is the SMC sheet machine. This production equipment is a unit that integrates glass fiber cutting, sedimentation distribution (unsaturated polyester resin paste) impregnation, laminating, and winding. It is a device specifically used to produce SMC sheets.

TechnoFRP's SMC sheet machine has a reasonable structure, convenient operation, advanced control, small size, and high output, which is 2-3 times that of similar products.

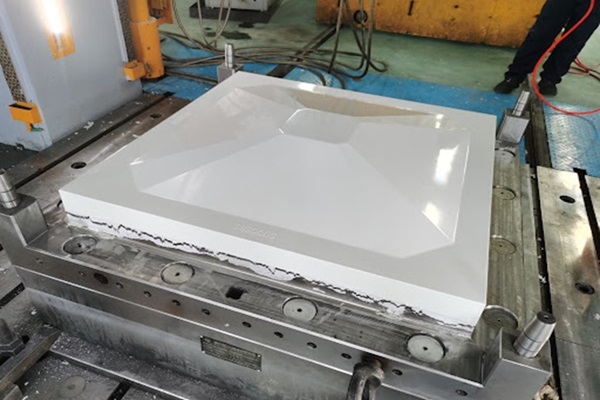

As a very professional SMC mold manufacturer, our SMC water tank mold has been fully polished and has a valve and center ejection system to achieve full automatic work. TechnoFRP's high-precision mold manufacturing technology ensures the tightness of your water tank. We can also customize different sizes of SMC and GRP water tank plate molds according to your needs.

SMC composite material compression molding hydraulic press is mainly responsible for the compression molding process in the product process, using various molds through high pressure and thermosetting molding.

The FRP water tank panel uses SMC sheet molding compound, which is molded once by a hydraulic press and mold under high temperature and high pressure. A hydraulic press can produce FRP water tank products of different sizes and specifications by replacing molds of different shapes.

Multi spindle drilling machine is an efficient equipment for processing fiberglass water tank panels. It is mainly used to efficiently drill multiple evenly distributed holes on the plate to ensure accurate alignment of assembly holes, interface holes, etc., to meet the needs of water tank plate installation and assembly. This type of equipment can significantly improve processing accuracy and efficiency while reducing manual operation errors. TechnoFRP has both automatic and semi-automatic drilling machines.

Final Products

SMC modular FRP water tank is assembled by SMC molded single plate, sealing material, metal fasteners, and piping system. The GRP sectional water tank panel increases the seismic and impact resistance, overcomes the uneven strength of hand-laid products, and improves the compressive strength and service life. In terms of appearance design, the middle of the plate is concave, which improves the pressure-bearing capacity of the water tank. At the same time, there are no 45-degree and 90-degree flanges around the plate, and no corner connectors are required during assembly, which is more flexible.

FRP water tank panels have the advantages of no leakage, are lightweight, have good water quality, beautiful appearance, long service life, and easy installation. It is widely used in industrial and mining, enterprises, institutions, residences, hotels, restaurants, and other buildings as drinking water, reclaimed water treatment, fire water, and other water storage facilities. In addition to providing processing equipment, technoFRP also provides molded FRP water tank panels.

The specifications of water tank plates are: 1000×1000mm, 1000×500mm, and 500×500mm.

The thicknesses are: 5mm, 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, and 22mm.