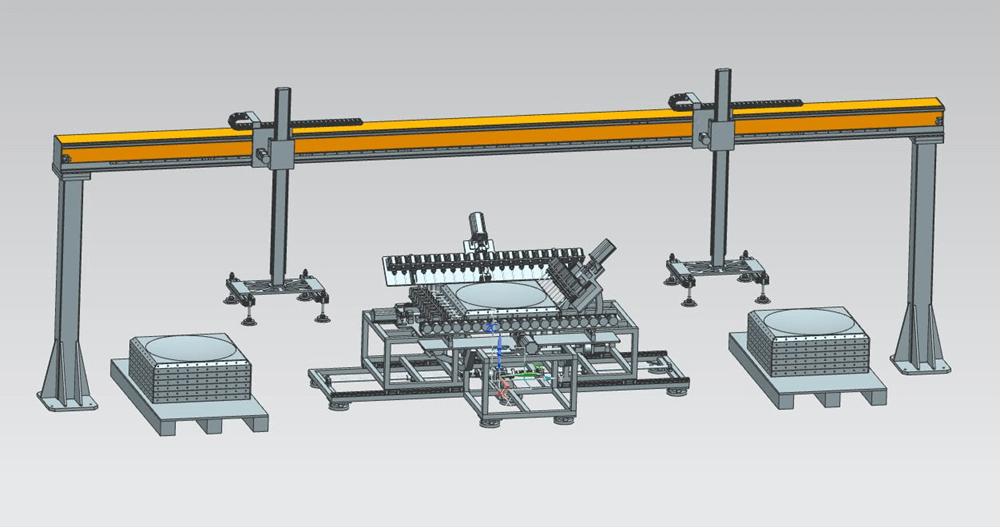

SMC Water Tank Panel Hole Automatic Drilling Machine

The SMC water tank plate automatic drilling machine is an efficient and intelligent equipment specially designed for drilling water tank plates made of SMC materials. This equipment adopts a multi-drill bit design combined with a CNC system. It has the characteristics of fully automatic operation, high-precision drilling, and rapid production. It can significantly improve production efficiency and reduce labor costs. Its flexible customization functions can meet diverse processing needs, and it is equipped with intelligent chip removal, cooling system and safety protection devices to ensure that the equipment operates efficiently while maintaining stability and safety. It is suitable for large-scale assembly line production and is an ideal choice to improve water tank panel manufacturing quality and productivity.

Structure of SMC water tank panel drilling machine

The structural design of the SMC water tank panel automatic drilling machine is mainly centered on completing the drilling operation of SMC plates efficiently and accurately.

1. Frame structure

• Machine tool base and bracket: These provide stability and support for the entire machine, usually using a solid steel structure to support the equipment’s weight and reduce vibration.

• Guide rail system: Installed on the frame to ensure the smooth movement of the drilling head, usually using high-precision linear guides.

2. Drill system

• Multi-axis drilling head: According to processing requirements, multiple drills are configured and usually installed on a multi-axis system. The drill can perform multi-point drilling at the same time to improve production efficiency.

• Drill power unit: Each drill is driven by an independent servo motor, which controls the drilling depth, speed and accuracy.

• Drill fixture and tool system: These are used to fix and replace the drill to ensure drilling accuracy. Some machines may be equipped with an automatic drill replacement system to facilitate processing different hole diameters.

3. Workbench and clamping system

• Mobile workbench: The part that loads the SMC water tank plate is usually designed as an automated mobile workbench, which can accurately move the plate position in conjunction with the positioning of the drill bit.

• Clamping device: The workbench is equipped with an automatic clamping device to fix the SMC plate, preventing displacement during drilling and ensuring processing accuracy.

4. Automatic control system

• CNC system: used to control the automated operation of the entire drilling machine, including programming control of parameters such as drilling position, number of drill bits, and drilling depth.

• Touch screen operation interface: Human-computer interaction interface, where workers can set processing parameters, view operating status, and perform fault diagnosis.

• Positioning system: Equipped with a high-precision automatic positioning system to ensure that the position of each drill is accurate.

5. Automatic chip removal system

Drilling waste removal: The equipment is usually equipped with an automatic chip removal system, which removes the waste generated by drilling through a conveyor belt or exhaust device to keep the working area clean and avoid affecting subsequent operations.

6. Cooling system

Drilling cooling device: To prevent the drill from overheating during high-frequency drilling, a coolant injection system is usually configured to reduce the drill temperature, extend the tool life and ensure a smooth machined surface.

Advantages of SMC Water Tank Automatic Drilling Machine

The advantages of the SMC water tank plate fully automatic drilling machine mainly revolve around its high efficiency, accuracy and automation features, which can bring significant productivity improvements and cost reductions to production companies. The following are the advantages of TechnoFRP’s automatic drilling machines.

1. Fully automated operation

• High-efficiency production: Without manual intervention, the equipment can automatically complete the drilling work of SMC water tank plates, greatly increasing production. The automated system can precisely control the location and quantity of drilling holes, reducing human errors.

• Reduce labor costs: Automation means less reliance on skilled workers, reducing labor costs in the production process.

2. High-precision drilling

• Precise positioning: Advanced numerical control (CNC) technology ensures a high degree of consistency in drilling positions, and the error is controlled within a very small range. It is especially suitable for processing water tank plates with high precision requirements.

• Multi-drill bit design: Multiple drill bits work simultaneously, which can quickly complete the processing of multiple holes, ensuring the perfect combination of processing speed and accuracy.

3. Adapt to diversified production needs

• Strong flexibility: The equipment can be adjusted according to different SMC plate specifications, thickness and hole spacing requirements and supports the processing of different types of water tank plates with wide adaptability.

• Customized support: The equipment can be customized according to the customer’s specific needs, such as the number of drill bits, workbench size and fixture type, to meet personalized production.

4. High speed and stability

• High production speed: Combining multi-drill design and automatic positioning greatly improves production efficiency. Compared with traditional manual drilling, the speed can be increased several times, which is suitable for large-scale assembly line production.

• Long-term stable operation: The equipment adopts high-quality servo motors and linear guide systems to ensure stability during long-term work and reduce downtime and maintenance frequency.

5. Intelligent control

• Easy-to-operate CNC system: Equipped with a touch-screen operation interface, the system allows users to easily set processing parameters and monitor the equipment status in real-time, ensuring convenient and intuitive operation.

• Automatic fault diagnosis: The equipment has automatic fault detection and alarm functions, so operators can quickly resolve problems and reduce downtime.

6. Efficient chip removal and cooling system

• Automatic chip removal device: The machine is equipped with an automatic chip removal system that discharges the waste chips generated during the drilling process in time, keeps the working area clean, and effectively improves work efficiency.

• Cooling system: Equipped with a drill cooling system to prevent the drill from overheating during high-intensity work, extend the service life of the equipment, and improve the processing quality.

7. Reduce defective rate

• High consistency: Through fully automated control, the equipment ensures the drilling accuracy and consistency of each SMC water tank plate, reducing the defective rate and rework cost.

• Stable quality: Whether it is long-term continuous production or high-precision processing tasks, the machine can maintain stable quality output.

8. Full solution

• High integration: The equipment can be seamlessly integrated into the production line of SMC water tank panels and cooperate with other equipment (such as SMC molding machines and cutting equipment) to form a fully automatic assembly line.

• After-sales and technical support: Provide comprehensive after-sales service and technical support to help customers quickly get started and provide timely maintenance and technical upgrade suggestions during use.

These advantages make the SMC water tank drilling machine efficient, stable and cost-effective, especially suitable for manufacturing companies that require large-scale, precise production.

Application of SMC water tank panel hole automatic drilling machine

SMC water tank automatic drilling machine is widely used in the production of SMC (sheet molding compound) water tanks, storage tanks and other products. It can quickly and accurately drill holes for water tank plates for subsequent splicing and installation. It mainly serves industries that require a large number of high-quality SMC water tank panels, helping companies increase production capacity, improve product quality, and reduce production costs.