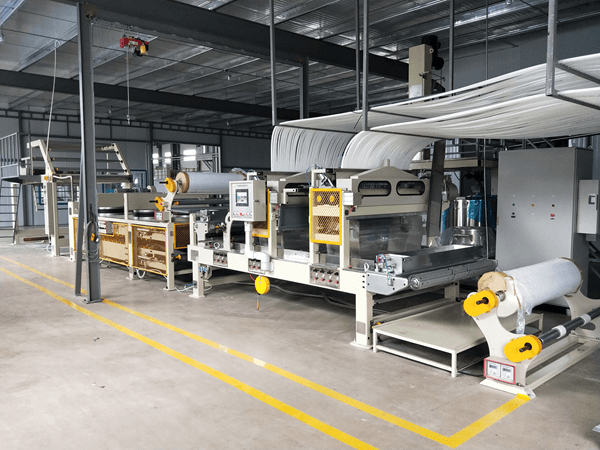

SMC Sheet Machine

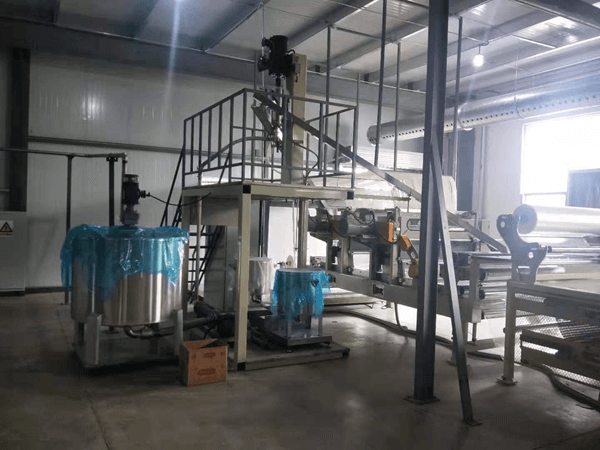

The SMC sheet machine mainly produces unsaturated polyester glass fiber reinforced sheet molding compound. It is a polyester paste with resin, filler, pigment, release agent, etc., impregnated with glass fiber yarn and covered with film on both sides to form a “sandwich structure,” “rolled” or “folded” “sheet molding compound.” Glass mat, glass cloth, and oriented yarn can be used to produce sheets with different strength requirements.

TechnoFRP‘s SMC sheet machine is simple and convenient and can be manual or automatic. Manual operation can be performed separately as required. Automatic operation can be performed with one button. Our factory can produce different sheet machines according to customers’ requirements for single knife, double knife, ton packaging, product width, synchronous speed regulation, etc.

SMC sheet machine composition:

1. The functional parts of the machine are the paste area, cutting area, impregnation area, and material collection area.

2. The main frame is welded with high-quality carbon steel square tubes and special-sized rectangular tubes to ensure the unit’s overall stability.

3. SMC sheet production speed: 1-12m/min. The speed is continuously adjustable. With good impregnation, the production speed can reach 2.5 tons per hour or more when the film’s tensile strength is reached.

4. The knife roller of the SMC sheet machine adopts the German spiral form.

(1) Can cut out half-inch, one-inch, one and a half inches, and two-inch short-cut fibers.

(2) Can be used with continuous unidirectional long fibers.

(3) A glass fiber mat or glass fiber mesh can be used.

5. Set up a continuous long fiber feeding rack and a glass fiber cloth or fiber mat placement rack to ensure the stability of the product and improve the strength of the product.

Features of SMC sheet machine:

1. Strong specialization: The SMC sheet machine is specially designed to produce SMC sheets, which can process SMC materials efficiently and ensure the stability of the production process and product quality.

2. High production efficiency: TechnoFRP’s SMC sheet machine has high production efficiency and can complete the production of many SMC sheets in a short time. For example, the productivity of some models of SMC sheet machines can reach 100-900m/hour, and the specific production speed can also be adjusted according to actual needs.

3. High degree of automation: Our SMC sheet machine adopts advanced automatic control technology. It can realize the whole process from raw material feeding to product forming. Reduce manual intervention and improve production efficiency and product consistency.

4. Stable structure: The main frame of the SMC sheet machine is welded with high-quality carbon steel square tubes and special specifications of rectangular tubes. It ensures the overall stability and durability of the sheet machine. This stable structure helps to reduce vibration and noise during the production process and improves the comfort of the production environment.

5. Complete functions: TechnoFRP’s SMC sheet machine has multiple functional areas, such as paste area, cutting area, impregnation area, and material collection area, which can meet the needs of different production stages. At the same time, we can also customize the design according to customer needs to meet specific production requirements.

6. Environmental protection and energy saving: With the improvement of environmental awareness, our SMC sheet machine also pays more attention to environmental protection and energy saving in design. By optimizing the production process and adopting energy-saving technology, we can reduce energy consumption and environmental pollution and achieve sustainable development.

Application of SMC sheet machine

SMC sheet machines are important equipment widely used in the manufacturing industry, especially in the automobile, electronics, and construction industries. It uses sheet or film materials, usually composite materials such as synthetic fiber and thermoplastics, to make lightweight, high-strength, and corrosion-resistant parts.

In summary, as an SMC sheet machine manufacturer, TechnoFRP’s SMC sheet machine is an efficient, stable, and automated production equipment that can meet the market demand for high-quality and efficient SMC sheets. If you have any needs, contact us immediately.