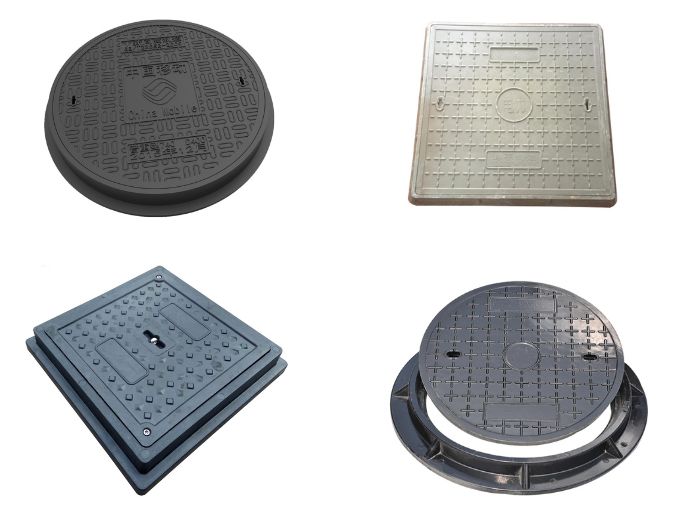

SMC Manhole Covers

SMC manhole cover is also called sheet molded manhole cover. It is a high-strength composite product made by impregnating a mixture of unsaturated polyester resin, thickener, initiator, crosslinker, low shrinkage additive, filler, internal release agent, colorant, etc., through a special process, and then formed by high-temperature and high-pressure liquid pressure.

| Product Name | SMC Composite Manhole Cover | Model NO. | GTR900D-H |

| Shape | Round | Certification | ISO, CE |

| Type | Moulding | Usage | Road Traffic Safety |

| Loading | A15/B125/C250/D400 | Standard | En124 |

| Color | Customized | Weights | 86kg |

| Features | Environmental Protection and Anti-Theft | Surface | Smooth Surface |

| OEM | Any Surface Design or Logo Are Fully Supported | Service Life | More Than 30 Years |

| Recovery Value | Zero | Working Temperature | -40°c-200°c |

| Conduction | Non-Electricity Conduction and Non-Heat Conduction | Transport Package | Manmade Wooden Pallet, Pallet Size 1100*1100*1200mm |

| Characteristics | Resistant to Ageing and Impact | Trademark | TechnoFRP |

TechnoFRP is a well-known SMC manhole cover manufacturer and supplier in China, producing and wholesale high-quality SMC manhole covers. If you need anything, don’t hesitate to get in touch with us.

1. Classification of SMC manhole covers

SMC manhole covers can be classified according to their use, load-bearing capacity, etc.:

• Classification by use: road manhole covers, drainage manhole covers, power manhole covers, communication manhole covers, etc.

• Classification by load-bearing capacity: light manhole covers, medium manhole covers, heavy manhole covers, etc., suitable for places with different load requirements.

• Classification by shape: round manhole covers, square manhole covers, rectangular manhole covers, etc.

2. Characteristics of SMC manhole covers

1) High strength: SMC materials have excellent mechanical properties, and the manhole covers are high in strength and not easily damaged.

2) Lightweight: Compared with traditional cast iron manhole covers, SMC manhole covers are lighter and easier to transport and install.

3) Corrosion resistance: SMC materials are resistant to acid and alkali corrosion and are suitable for various complex environments.

4) Anti-aging: The manhole covers have good weather resistance and are not easy to age after long-term use.

5) Good anti-theft performance: Some SMC manhole covers have locking devices to prevent theft.

6) Strong insulation: Suitable for places such as electricity and telecommunications that require insulation performance.

3. Advantages of SMC manhole covers

• Good environmental protection: SMC materials are non-metallic and have no recycling value, reducing the risk of theft and meeting environmental protection requirements.

• Long service life: SMC manhole covers are corrosion-resistant and anti-aging, and their service life can reach more than 20 years.

• Aesthetics: The surface is flat and smooth, and the color and pattern can be customized to enhance the urban landscape’s aesthetics.

• Easy to maintain: The manhole cover is reasonably designed, easy to install and replace, and reduces maintenance costs.

4. Detailed parameters of SMC manhole covers

1) Carrying capacity: From light to heavy, the carrying capacity ranges from 12.5 tons to more than 40 tons.

2) Size: The diameter of the round manhole cover is usually 600mm, 700mm, etc.; the size of the square manhole cover is 500x500mm, 600x600mm, etc.

3) Thickness: The thickness of the manhole cover is generally between 20mm and 60mm, depending on the load requirements.

4) Weight: Depending on the size and thickness, the weight ranges from 10kg to 50kg.

5) Color: Common colors include black, gray, green, etc., which can be customized according to needs.

5. Application of SMC manhole covers

SMC manhole covers are widely used on municipal roads, residential areas, industrial parks, parking lots, airports, docks, and other places. It is suitable for the wellheads of various underground facilities such as communications, electricity, drainage, gas, and water supply.

6. Raw materials for SMC manhole covers

SMC (Sheet Molding Compound) material is the key to manufacturing SMC manhole covers. It is mainly composed of the following raw materials:

• Unsaturated polyester resin: This is the matrix resin of SMC materials, which plays the role of bonding and molding. It has good chemical resistance, mechanical properties and electrical insulation.

• Glass fiber: As a reinforcing material, glass fiber can significantly improve the strength and rigidity of SMC materials. Typically, chopped glass fibers are used, evenly distributed in the resin, enhancing the material’s tensile strength and impact resistance.

• Fillers: Commonly used fillers include calcium carbonate, talc, wollastonite, etc. These filters can increase the density and stiffness of the material, reduce costs, and improve the dimensional and thermal stability of the material.

• Auxiliaries: including various accelerators, cross-linking agents, release agents and thickeners, etc. These additives play a role in adjusting viscosity, promoting curing, improving fluidity and improving processing performance in the resin.

• Pigments: Used to color SMC materials. Manhole covers of different colors can be customized as needed.

7. Manufacturing process of SMC manhole cover

1) SMC sheet preparation

Raw material mixing: First, unsaturated polyester resin is mixed with fillers, additives and pigments to form a uniform resin base. Then, chopped glass fiber is combined with the resin base on a continuous production line to form a sheet molding compound.

Sheet rolling: The mixed material is coated on a film, and through multi-layer stacking and compaction, it is made into a prepreg sheet (SMC sheet), which is then rolled into a roll for storage and use.

2) Compression molding

Slice preforming: According to the size and shape requirements of the manhole cover, the SMC sheet is cut into pieces of suitable size with an SMC sheet machine and placed in the mold of a hydraulic press.

Heating compression molding: The SMC manhole cover mold is closed at a high temperature, and high pressure is applied after heating to a certain temperature to fill and mold the SMC sheet in the mold. This process is usually carried out between 150°C and 170°C, and the pressure can reach tens of MPa.

Cooling and curing: The mold remains pressurized and gradually cools down to solidify the material. The cured manhole cover will retain the shape and surface texture of the mold.

3) Post-molding processing

Demolding: After the mold cools to a certain temperature, open the SMC manhole cover molding machine and take out the molded manhole cover.

Trimming: Trim and polish the manhole cover to remove excess burrs to ensure dimensional accuracy and surface finish.

Surface treatment: As needed, the surface of the manhole cover can be additionally treated, such as coating, logo printing, etc., to improve its weather resistance and aesthetics.

Quality inspection: Quality inspection of the finished manhole cover, including dimensional measurement, load-bearing capacity test, corrosion resistance test, etc., to ensure that it meets the standard requirements.