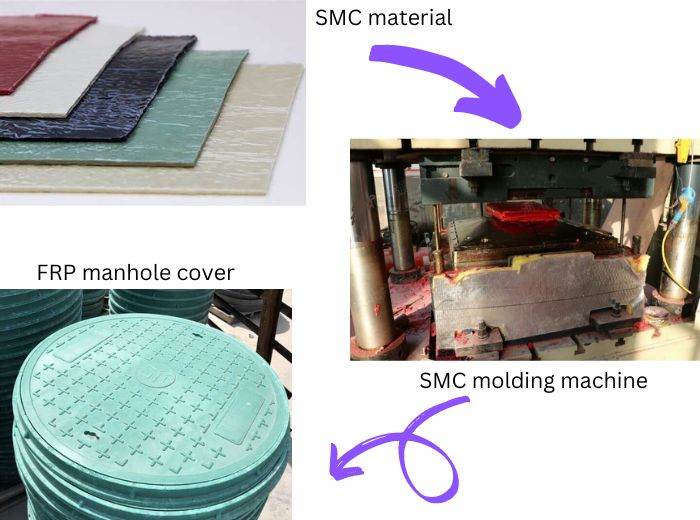

SMC Manhole Cover Molding Machine

A resin manhole cover is a manhole cover made of composite materials processed by high-temperature mold, which belongs to the composite material hot-pressing molding process. The main equipment required includes resin manhole cover hot pressing molding hydraulic press, mold, heating equipment (mold temperature controller or electric heating, oil heating), kneading machine, etc. Among them, the hydraulic press is the main production equipment.

The body of TechnoFRP’s 315-ton SMC manhole cover molding machine adopts all-steel CO2 welding and is annealed after welding. Eliminate welding internal stress to ensure that the body will never deform. The hydraulic system is located inside the body, with a beautiful appearance and easy operation. This series of presses is equipped with independent hydraulic and electrical control systems and is centrally controlled by buttons. It can realize two molding processes, fixed stroke and fixed pressure, with pressure display and stroke, pressure adjustment, and other functions. It is suitable for a variety of SMC composite material compression molding processes.

Main structure of the 315T SMC manhole cover molding machine:

The 315-ton SMC manhole cover press comprises the main machine, the hydraulic system, and the control mechanism. The main machine includes the machine body, the oil cylinder, the oil tank, etc. The hydraulic system includes the motor, the oil pump, the valve block, the valve parts, the pipeline, etc. The control mechanism includes the travel limit device, the pipeline and the electrical control box, etc.

The details are as follows:

(1) Machine body: The machine body is an integrally welded four-column structure made of steel plates. It is stress-relieved after welding.

(2) Hydraulic cylinder: Made of 45# steel. The main oil cylinder is a single-piston cylinder. The surface of the piston rod is chrome-plated. The motion guide of the piston rod adopts a non-metallic wear-resistant ring.

(3) Stroke control device: The proximity switch detects and controls the stroke of the main oil cylinder. When the distance between the upper and lower tables reaches 850mm, the upper table can immediately stop moving downward.

(4) Electrical system: PLC programming control is adopted, and components use brand components.

(5) Others: The equipment’s dangerous parts, such as rotating shafts and couplings, are equipped with protective devices. The operation panel has emergency stop, pause, and other protective buttons.

Features of 315-ton SMC manhole cover hydraulic press:

1) With heating function. The mold is heated by electric heating or by a mold temperature controller.

2) Equipped with a mold-opening cylinder with a micro-opening function.

3) With exhaust function, the SMC composite material is fully integrated, and the strength meets the performance requirements.

4) It is Equipped with external ejection and core pulling, a blowing system, and a vacuum system. Our hydraulic press is suitable for producing precision SMC composite products such as home appliance housings and auto parts.

5) Equipped with a mold-changing trolley for easy loading, unloading, and changing molds.

6) Equipped with a green environmental protection system and a smoke collection hood. Centralized treatment of exhaust gas in line with the requirements of the environmental protection department and worry-free production.

7) Equipped with a four-corner leveling system to meet high-precision requirements.

Production process steps of SMC manhole cover:

1. Prepare the evenly stirred SMC resin composite material.

2. Measure and load the resin raw materials into the mold of the required model.

3. Place the welded steel frame into the mold and fix it firmly.

4. Mix the remaining resin raw materials into the mold evenly.

5. Start the 315-ton SMC manhole cover molding machine to press the product.

6. The product gradually solidifies and forms under the mold’s high temperature and the machine’s high pressure.

7. When the holding time is up, the hydraulic press starts to return. After forming the product, remove it from the mold and cool it down.

8. After taking out the product, clean the burrs, make it smooth all around, and place it stably. Prevent deformation.

9. After the product is cooled, install the required accessories and conduct a 1-meter free fall weight test.

Parameters of SMC manhole cover molding machine

| Project | Unit | 315T | 500T | 630T |

| Maximum liquid pressure | MPa | 25 | 25 | 25 |

| Slider stroke | mm | 800 | 600 | 900 |

| Maximum opening height | mm | 1250 | 1000 | 1500 |

| Workbench size | mm | 1260X1200 | 1500X1500 | 1600X1600 |

| Downward speed of idle stroke | mm/s | 100 | 120 | 120 |

| Working speed | mm/s | 6-15 | 6-15 | 5-12 |

| Return speed | mm/s | 80 | 80 | 90 |

| Motor power | KW | 22 | 18.5X2 | 22X2 |

| Oil pump displacement | ml/r | 80 | 63X2 | 63X2 |

| Ejection force | t | 63 | 100 | 100 |

| Ejection stroke | mm | 250 | 300 | 300 |

TechnoFRP is a professional hydraulic press supplier in China and provides high-quality composite material molding machines. Contact us now!