Sigma Mixer | Sigma Mixer Manufacturer

Sigma Mixer is used to knead, mix, crush, disperse, and re-polymerize high-viscosity paste or elastoplastic materials, which can not be processed by available powder mixers and liquid blenders.

Sigma kneader is the ideal equipment for all kinds of chemical products and has the merits of stirring evenly, kneading efficiently, and having no dead corners. The materials are scraped, stretched, folded, and squeezed among the blade, slot wall, and ridge-like protrusions. The materials cycle from one end of the impeller to the other. The two mixing paddles are tangent and spin at different speeds to complete the kneading process.

The horizontal sigma mixer provides universal kneading of ultra-high viscosity materials. The kneading effect (kneading, crushing, dispersing) is maximized by the strong shear forces generated between the two strong blades and between the blades and the kneading grooves. Cooling, heating and vacuum/decompression are also options. TechnoFRP is committed to ensuring quality and quantity and providing you with high standards, high requirements, and high-quality BMC kneading machines.

Working Principle of Sigma mixer

A Sigma blade mixer, also known as a double arm mixer or kneader, is a type of mixing equipment commonly used in the chemical and food processing industries. It is designed to knead and mix high-viscosity materials, pastes, doughs and other viscous substances.

A sigma kneader consists of two blades, usually in an “S” or “∑” shape. They are mounted on parallel shafts and rotate in opposite directions. The blades are usually curved or angled to form a trough-shaped mixing chamber. The rotation of the Sigma blade creates a shearing action that causes the material to be kneaded, folded and thoroughly mixed.

Sigma blade mixers provide efficient and thorough mixing capabilities, especially for high-viscosity and viscous materials. They ensure uniform distribution of ingredients, enhance product consistency and facilitate the development of desired product characteristics in a wide range of industries.

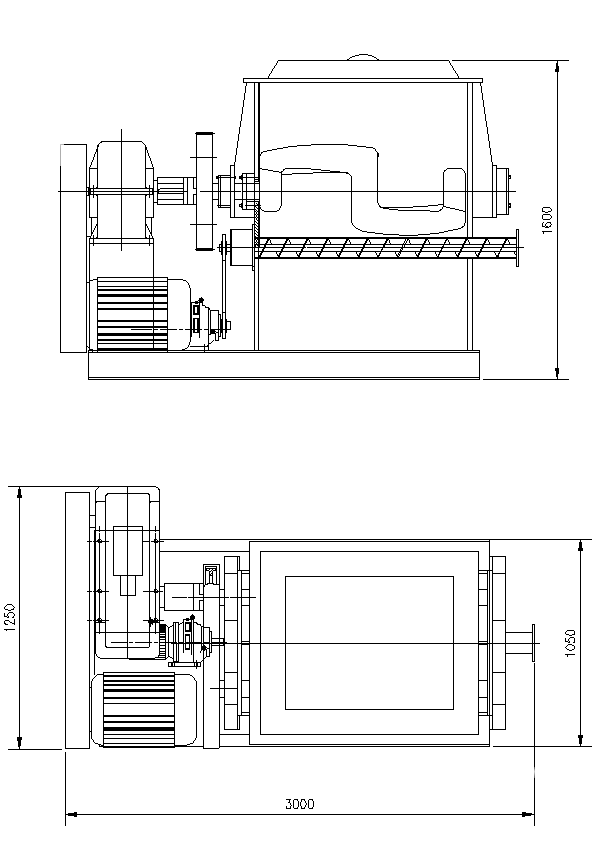

Drawing of Sigma kneader

Sigma mixer blades

Sigma blades are the most common blades. It is optimum for kneading materials that require a large movement inside the kneading trough. It is mainly used in an overlapping arrangement and is particularly superior for materials processed by flushing. It is commonly used for printing inks, chocolate, carbon pitch, etc.

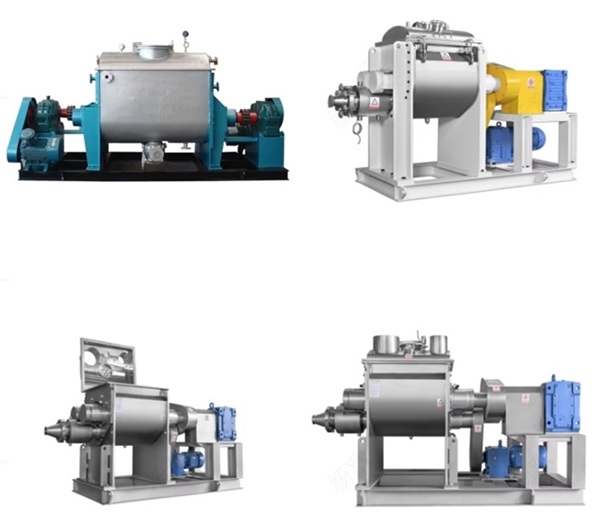

Sigma kneader category

There are four kinds of Sigma mixers: Vacuum kneader, pressure kneader, atmospheric pressure kneader, and high-temperature kneader.

It has three ways of discharging: Hydraulic tilting, ball valve, and screw extrusion.

Advantages of Sigma blade mixers:

* Intensive kneading and dispersion of high-viscosity products.

* Short processing time and improved product quality.

* Minimum processing volume is 25% of the total container volume.

* Infinitely variable speed adjustment via frequency converter.

* Automation according to customer requirements.

* All metal parts in contact with the product are made of AISI 316L / 316Ti stainless steel.

* Seals are made of high-quality materials.

Applications of Sigma mixers:

♦ Technical ceramics

♦ Hot-melt adhesives

♦ Manufacture of abrasives

♦ Graphite compounds

♦ Sealing compounds

♦ Lubricants

♦ Hard metal compounds

Parameter of Sigma kneaders

| Model(L) | NH-5 | NH-10 | NH-50 | NH-100 | NH-200 | NH-300 | NH-500 | NH-1000 | NH-1500 | NH-2000 | NH-3000 | NH-4000 | NH-5000 | NH-6000 | |||

| Volume(L) | 5 | 10 | 50 | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | |||

| Steam pressure(Mpa) | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | |||

| Hot oil circulation(Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |||

| Electric heating(Kw) | 1.5 | 2 | 3-6 | 4-11 | 6-15 | 6-18 | 12-24 | 18-36 | 32-45 | / | / | / | / | / | |||

| Fast rpm | 60 | 45 | 35 | 36 | 36 | 40 | 30 | 35 | 40 | 35 | 32 | 30 | 35 | 35 | |||

| Slow rpm | Speed ratio 1.0-1.9 is an option, according to materials features. | ||||||||||||||||

| Main motor (Kw) | 0.55-1.5 | 0.75-2.2 | 1.5-3 | 4-11 | 5.5-15 | 5.5-18 | 11-45 | 18.5-75 | 22-90 | 45-160 | 55-190 | 75-250 | 90-225 | 90-225 | |||

| Vacuum |

≤-0.094Mpa |

||||||||||||||||

| Discharge | 1.Manual(for small capacity) 2.Bottom ball valve 3. Electric tilting 4. Screw extruding | ||||||||||||||||

Notes:

(1) Our company can design the equipment according to user requirements.

(2) For the last update of the technology, we will change the technical data without notice, and the correct parameters are subject to the real product.

(3) If you are unsure which type to choose, please call us, and our professional sales engineers will recommend one for you.

Details of Sigma blade mixers