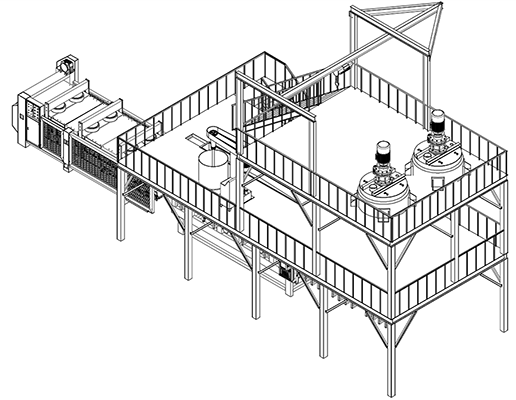

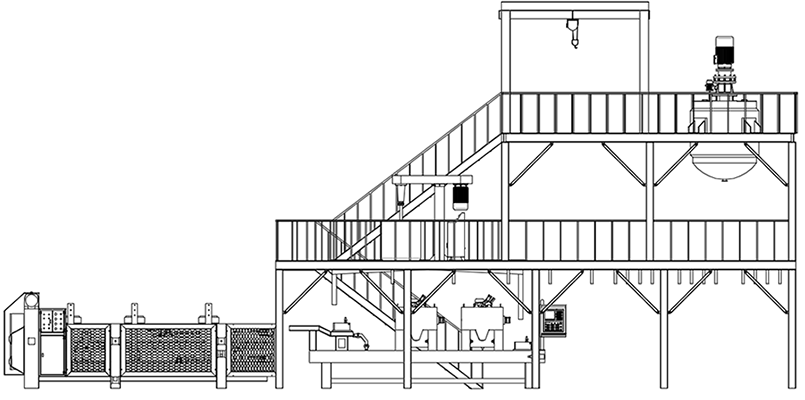

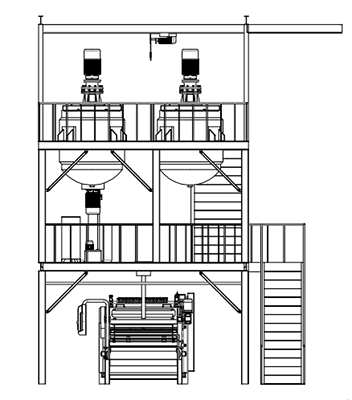

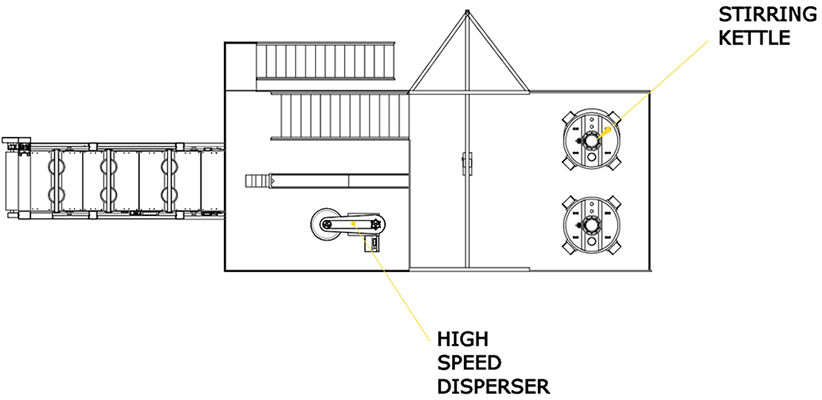

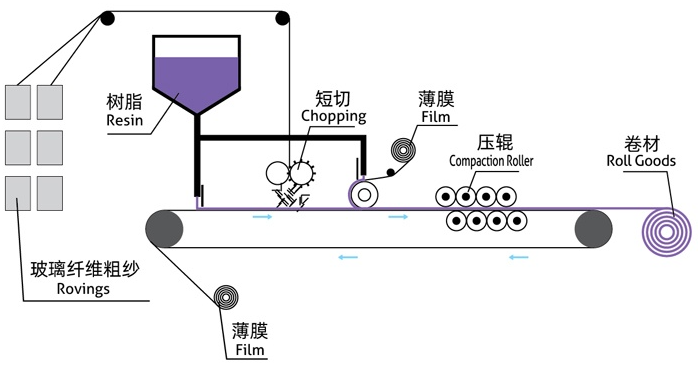

Sheet Molding Compound Machine

TechnoFRP is a professional sheet molding compound machine manufacturer in China. We provide high-quality SMC sheet machines and a complete sheet molding compound machine production line, enabling us to provide our customers with perfect SMC molding solutions.

|

Name |

Unit |

Value |

Remark |

|

Name of machine |

|

SMC Production Line |

|

|

Model |

|

SMC-1000 |

|

|

Plastic film width |

mm |

1100 |

|

|

Film Max. diameter |

mm |

400 |

|

|

SMC Sheet width |

mm |

Max. 1000 |

|

|

Productivity |

m/h |

3-700 |

Adjustable |

|

Resin paste viscosity |

Mpas |

10000-35000 |

According to the formula |

|

Fiber content 10%-40% |

According to user needs |

||

|

Blade gap |

mm |

≤0.03 |

|

|

Fiberglass model |

tex |

2400-4800 |

|

|

Number of glass fibers |

1/set |

32-42 |

2 sets |

|

Fiberglass length |

mm |

12.5-25-37.5-50 |

Set by blade |

|

Slicer

|

Set |

2 |

|

|

Fiber dispersion uniform device |

Set |

2 |

|

|

Exhaust device |

Set |

5 |

|

|

Dipping zone speed |

m/min |

3-20 |

Adjustable |

|

Dipping zone mesh belt width |

mm |

1050 |

|

|

Dipping zone length |

mm |

5140 |

|

|

Main motor power |

KW |

4 |

Inverter control |

|

Cutting motor |

KW |

2.2*2 |

Inverter control |

|

Winding motor |

KW |

2.2 |

Inverter control |

|

Dimensions |

mm |

12000x2400x1900 |

|