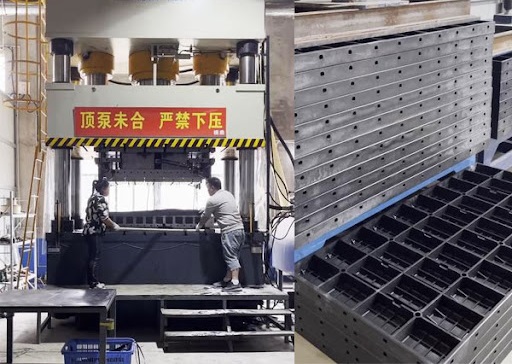

Plastic Pallet Molding Machine

Plastic pallets are usually made of high-density polyethylene (chemical name: HDPE), polypropylene (chemical name: PP), PVC, etc. Plastic pallets are mostly made of waste plastics. The solid plastic is softened by heating it with an extruder, and then the softened plastic is placed in a mold. The plastic pallet hydraulic press acts on the mold. Under high pressure, it is molded in one step. After cooling, the pressed plastic pallet is taken out.

Molded plastic pallets easily achieve specialized and mechanized production, can be mass-produced, and require little recycled waste. The resulting pallets have high dimensional accuracy and good repeatability. Therefore, in recent years, many companies have adopted this molding process to reduce costs and improve production efficiency.

Features of plastic pallet molding machine

1. Three-cylinder four-column structure, stable structure, a four-column guide to ensure accurate mould clamping.

2. A servo motor is used, with low working noise. The press runs smoothly, and the control is more precise.

3. Siemens control system and Schneider electrical components are used.

4. It has the main features of rapid prototyping, energy saving and environmental protection.

5. The plastic pallet molding machine adopts a four-column guide structure with high accuracy and strong anti-eccentric load. It is suitable for products with high-pressing accuracy requirements.

6. Computer-optimized design of the whole machine, three-beam four-column structure, simple, economical and practical.

7. Forged steel is finely processed and thickened, with good rigidity and strong anti-deformation.

8. High output. The equipment can have a fully automatic feeding and unloading stacking device with high production efficiency.

Parameter of plastic pallet molding machine

| SPECIFICATION | UNIT | YQ32-63T | YQ32-100TA | YQ32-100TB | YQ32-200TA | YQ32-200TB | YQ32-315TA | YQ32-315TB |

| Nominal force | KN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Max.System pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Max.Open height | mm | 700 | 800 | 900 | 1200 | 900 | 1250 | 1000 |

| Max.Stroke of slider | mm | 400 | 500 | 600 | 700 | 600 | 800 | 600 |

| Effective table size | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Down speed | mm/s | 180 | 120 | 120 | 100 | 100 | 100 | 100 |

| Pressing speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-11.5 | 7-11.5 |

| Return speed | mm/s | 100 | 120 | 120 | 70 | 70 | 60 | 60 |

| Ejection cylinder force | KN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Stroke of ejectioncylinder | mm | 160 | 200 | 200 | 220 | 220 | 300 | 300 |

Plastic pallet production line

The plastic pallet production line equipment includes a feeding system, plastic extrusion and plasticizing system, storage quantitative system, plastic pallet molding machine, cooling system and removal device.

The new compression molding technology is used to produce plastic pallets. TechnoFRP‘s production line has low raw material requirements, no granulation process, low investment, high output, and easy maintenance. At the same time, the pallet is of high quality, has high weight, and is low cost, which is a wise choice for reducing logistics, warehousing, and export costs.

Three major advantages of molded pallets

1. Low cost and low requirements for raw materials. Utilizing recycled plastics, industrial waste (leather scraps), agricultural waste (plastic film), etc., truly achieves waste recycling, reducing the burden of national waste disposal and production costs for enterprises.

2. The pallet is pressed and formed in one step, with strong strength and large load-bearing capacity.

3. Molded pallets are produced efficiently and have high output. Pallet molding can realize production automation. The fully automatic production line realizes full production automation through 7 links, including automatic batching, automatic weighing, automatic distribution, automatic flattening, automatic pressing, automatic tray discharge, and automatic stacking.