Plastic Pallet Mould/Mold

Plastic pallet mold is a high-precision industrial mold specially designed for the production of plastic pallets. It is used in combination with a hydraulic press to manufacture high-strength and durable plastic pallets through heating and high-pressure molding processes. This mold is widely used in logistics, warehousing, food processing, chemical industry and other industries to meet the needs of plastic pallets in different application scenarios.

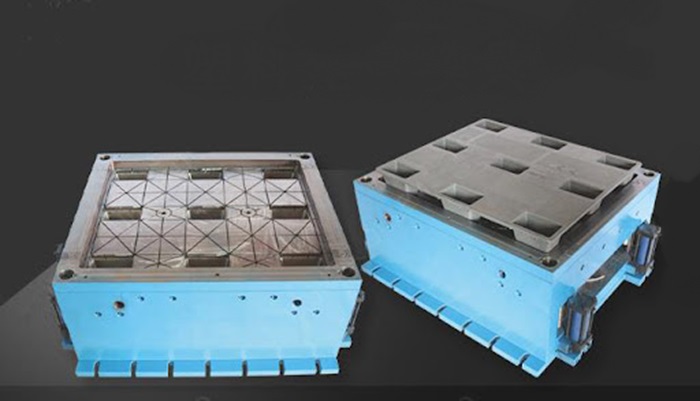

Plastic Pallet Mold Structure

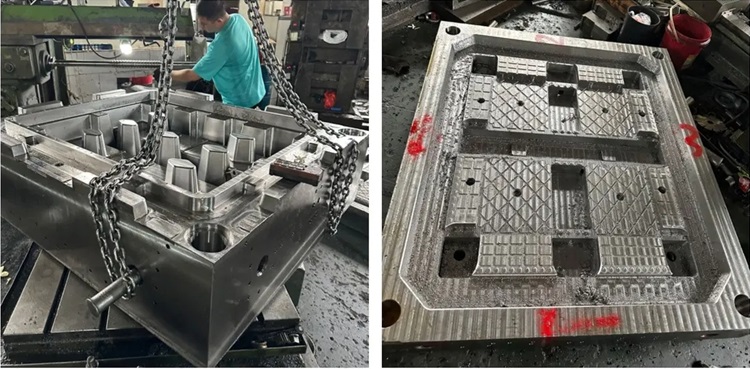

1. Mold composition

• Upper mold and lower mold: made of high-strength alloy steel, quenched, and surface treated to improve hardness and wear resistance.

• Molding cavity: designed as a grid or flat plate structure according to the shape of the pallet to ensure the dimensional accuracy and load-bearing capacity of the pallet.

• Mold frame: used to fix the mold and provide support to ensure the stability of the high-pressure molding process.

2. Heating system

• TechnoFRP‘s mold is embedded with a heating device (usually an electric heating tube or an oil heating system), which is evenly distributed on the mold surface.

• The precise temperature control system can control the mold temperature within the set range to ensure uniform heating of the plastic material.

3. Cooling system

Configure cooling water channels or oil cooling systems to quickly cool the molded plastic pallets after pressing is completed, shorten the demolding time and improve production efficiency.

Features of Plastic Pallet Mold

1. Efficient molding

The mold design is optimized to support one-time molding of plastic pallets of various sizes and thicknesses.

Precise heating and cooling system speeds up molding and demoulding, and improves production efficiency.

2. High temperature and high-pressure resistance

Use high-strength mold steel materials (such as H13, P20, etc.), quenched, and surface treated to ensure long-term operation under high temperature (180°C-250°C) and high pressure (20-50 MPa) conditions.

3. Precision machining

The mold surface is precision machined by CNC to ensure that the detailed design of the pallet grid, frame, ventilation holes, etc. fully complies with industry standards.

4. Modular design

Mold components can be replaced independently, which is convenient for maintenance and reduces maintenance costs.

5. Strong adaptability

Molds of different specifications can be customized according to customer needs, such as single-sided, double-sided, grid, or flat pallets.

Technical Parameters of Plastic Pallet Mold

• Mold size: customized according to pallet specifications (common specifications: 1200×1000mm, 1100×1100mm, etc.).

• Material selection:

· Mold steel: H13 steel, P20 steel, 420 stainless steel.

· Surface treatment: chrome plating or nitriding to enhance wear resistance and corrosion resistance.

• Applicable plastic materials: thermoplastics such as PP, HDPE, LDPE.

• Working temperature: 180°C-250°C.

• Pressure range: 20-50 MPa.

Application of Plastic Pallet Mold

1. Logistics and warehousing

Manufacture plastic pallets for transportation and storage, suitable for high loads and repeated use.

2. Food industry

Use food-grade plastic materials to produce pallets that meet hygiene requirements.

3. Chemical industry

Manufacture corrosion-resistant pallets for storing chemicals.

Advantages of Plastic Pallet Molds

1) Production stability: The design meets the needs of industrial-grade high-intensity production and has excellent long-term operating performance.

2) Customization flexibility: The shape and specifications of the pallet can be customized according to the industry needs of different customers.

3) Durability: The mold has a long service life and can produce more than 100,000 pallets on average.

4) Economic efficiency: Optimize the production process, reduce waste generation, and reduce comprehensive production costs.

Our Services

♣ Mold design and manufacturing: Provide standard or customized mold solutions according to needs.

♣ Technical support: Provide mold installation and debugging services to ensure efficient operation.

♣ Mold maintenance and upgrade: Provide mold renovation and accessory replacement services.

For more details or to order molds, please contact us for detailed solutions!