Glass fiber cloth is divided into high-alkali cloth, medium-alkali cloth and alkali-free cloth according to the alkali content. The lower the alkali content, the better the flexural and tensile strength. These kinds of cloths can be distinguished according to their electrical conductivity. The high-alkali cloth is a conductor and can be used as a wire. The medium alkali cloth is a semiconductor, and the alkali-free cloth is an insulator. The current optical fiber for information transmission is glass fiber transmission, which belongs to high-alkali cloth. Currently, the medium-alkali cloth is used for magnesite cement building materials, and the alkali-free cloth is suitable for circuit boards and electronic grades. So, what areas can fiberglass cloth play a role in?

Let’s take a brief look at it:

1) Electrical insulation: Silicone cloth has a high electrical insulation grade, can withstand high voltage loads, and can be made into insulating cloth, bushings and other products.

2) Non-metallic compensator: Silicone cloth can be used as a flexible connecting device for pipelines. It can handle the damage to pipelines caused by thermal expansion and contraction. Silicone cloth has high-temperature resistance, corrosion resistance, anti-aging properties, and excellent elasticity and flexibility. , can be commonly used in petroleum, chemical, cement, resources and other fields.

3) Anti-corrosion: Silicone rubber-coated glass fiber cloth can be used as a pipeline, a reserved internal and external anti-corrosion layer, with excellent anti-corrosion function and high strength. It is a dream anti-corrosion raw material.

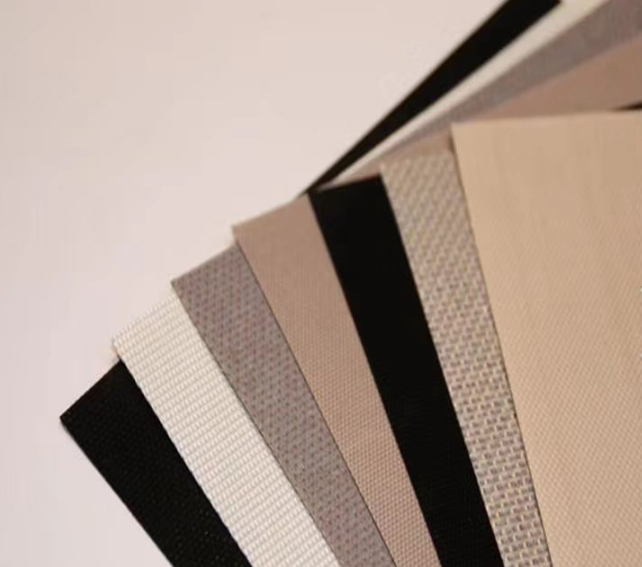

4) Other boundaries: Silicone rubber-coated glass fiber membrane structural materials can be used in construction sealing materials, high-temperature anti-corrosion conveyor belts, packaging materials and other boundaries. Color: silver gray, gray, red color, black, white, clear color, orange, etc. Type of coating: single-sided or double-sided.

TechnoFRP provides fiberglass raw materials. If you have any needs, contact us!

Post time: Sep-16-2022