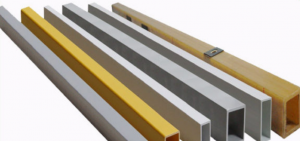

As one of the future composite materials technologies, pultrusion has received the attention of many composite materials people. It is to infiltrate continuous fibers or their fabrics with resin under the traction of the traction equipment, and heat the resin through the molding die to solidify the resin to produce composite materials. Process methods for material profiles.

1. Pultrusion

Pultrusion is a continuous process of manufacturing scrap with constant cross-section. Combining “pull” and “squeeze”, pultrusion stretches the material as opposed to the extrusion that pushes the material.

2. Processing of pultrusion

Veils can also be added to prevent erosion or “fiber bloom” and to provide corrosion and UV resistance.

The technology is not limited to thermoset polymers. At present, pultrusion has been successfully used with thermoplastic matrices such as polybutylene terephthalate (PBT), and polyethylene terephthalate (PET) by impregnating or wrapping the powder of glass fibers in a sheet of thermoplastic matrix, which is then heated.

Compared to composites based on thermoset resins, the ecological cleanliness of the finished product and the almost unlimited recycling (processing) possibilities after resource depletion seem to be compelling arguments in favor of reinforced thermoplastics.

For these reasons, industrial production and use of a given material has grown by 8-10% per year in highly industrialized countries in recent decades. New developments not only give a practical boost to the manufacture of both straight and curved profiles, especially in the automotive sector, but the demand for this technology is growing.

The pultrusion technique for making fiber composites from polymer matrices appears to be energy and resource efficient.

Both economic and environmental factors favor the use of thermoplastic matrices, but due to the high viscosity of the melt, it is difficult to achieve high productivity and high-quality fibrous filler impregnation with this type of matrices.

3. Application areas

Products manufactured using this technology are widely used in the following industries:

In the agricultural and chemical industries, for the manufacture of resistant, corrosion-resistant slatted floors with enhanced strength properties for the construction of livestock facilities, chemical plants, etc.;

In the construction industry, it is used to produce glass fiber-reinforced materials, profiles, carcasses, reinforcing bars for PVC windows, and other products.

Structural components are used in the manufacture of aircraft in the aerospace industry.

In sports and tourism, equipment for the manufacture of equipment with enhanced strength properties: snowboards, ski poles, golf course flagpoles, tent and shed structures, etc.

In electrical engineering, fiberglass is used to manufacture dielectric structures, fiberglass rods for composite insulators, support structures for signal block elements, and fiberglass profiles for transformers and electric motors.

In commercial production, long-fiber molding material (LLM) particles are used as raw materials to subsequently manufacture structures and products with enhanced strength and chemical properties.

In the automotive industry, it is used to produce vehicle structures and complex parts with enhanced stiffness, stiffness and lightness.

Boxer uses mechanisms, structures and materials that meet high standards for chemical, dielectric and strength stability in many other industries and factories.

4. Pultrusion equipment

Pultrusion machines vary in design. Two types that are often used are reciprocating (handover) and continuous (cat track).

For the fillet pultrusion process, the machine layout has two moving stages, similar to hand-pulled components handed over, but because the process is intermittent, only one puller and die are mounted on the other.

Whether the platform moves linearly or circularly depends on the type of profile to be manufactured. The minimum radius for a linear machine with a rotating platform is approx. 2 meters For smaller radii, circular motion of the die and gripper table is necessary.

Post time: Jul-05-2022