News

-

How does a Pultrusion Machine Work?

In this article, we mainly introduce the pultrusion machine’s working principles. What is pultruded fiberglass? Pultruded fiberglass rods are made from a composite of polyester resin and fiberglass. Their unique properties make them suitable for a wide range of applications in various industries,...Read more -

What is the Application Range of SMC Sheet?

1. Application in the automotive industry Suspension parts, front and rear bumpers, instrument panels, etc.; body and body parts, hard top panels, anti-skid floors, spoilers, sun hoods, hoods; lower hoods, wind deflectors, air intake duct covers, fan guide rings, engine baffles. Interior trim par...Read more -

How to Maintain SMC Sheet Machine?

During the production process of SMC sheet machines, maintenance and cleaning are very important, which can not only extend the service life of the equipment but also ensure production efficiency. The following are some common maintenance and cleaning steps: 1. Check the operation status of the e...Read more -

SMC Sheet Machine Finish Installation in Saudi Arabia Market

Congratulations to our Saudi customer who is about to put the new equipment into use. After two weeks of installation and commissioning, the equipment has been successfully installed. The SMC sheet produced by the customer company will be used to produce composite material manhole covers, trench ...Read more -

Our UAE Customer Starts to Install SMC Sheet Machine

After nearly two months of shipping by sea, the SMC sheet machine ordered by the UAE customer arrived smoothly. After the equipment arrived at the site, our after-sales installation engineering team also arrived, ready to provide customer after-sales service. To ensure the smooth operation of th...Read more -

Techno SMC Sheet Machine is Exported to the Egyptian Market

Recently, Techno’s SMC sheet machine was exported to Egypt and successfully completed factory acceptance. This equipment is a new type of thermosetting plastic sheet molding compound raw material machine mainly used to manufacture FRP SMC molding materials, which are widely used in the automotive...Read more -

SMC Sheet Machine Export to Saudi Arabia Market

Recently, TechnoFRP’s SMC sheet machine, which has a length of 1000mm, successfully overcame the epidemic's impact, guaranteed the delivery of equipment to Saudi Arabia on schedule, and entered the Middle East market again. This further expanded Techno’s brand radiation ...Read more -

Techno Company was Invited to Participate in Composite Technology Seminar

In recent years, with the rapid development of science and technology, many industrial fields have increasingly stringent requirements for material properties. Advanced composite materials have become a key factor affecting the development of all walks of life, and their development level has bec...Read more -

Pultrusion Process

As one of the future composite materials technologies, pultrusion has received the attention of many composite materials people. It is to infiltrate continuous fibers or their fabrics with resin under the traction of the traction equipment, and heat the resin through the...Read more -

Composite Compression Molding Process

Making FRP rebar with our FRP rebar pultrusion machine Features Specially designed for making FRP rebars, the machine can automatically complete roving guiding, impregnation, performin...Read more -

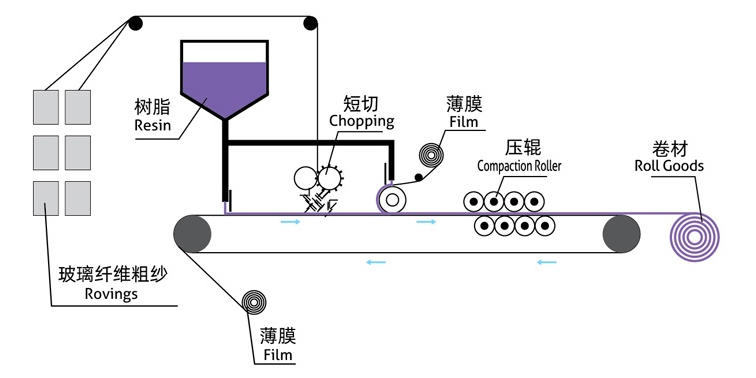

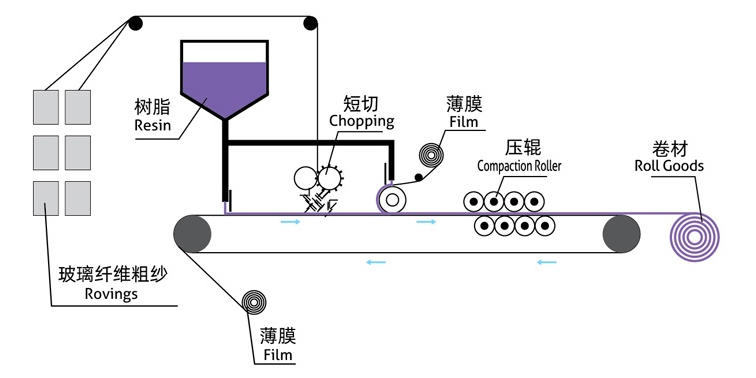

SMC Automatic Line

SMC is a resin paste formed by fully mixing resins, fillers, and other materials on the lower film. Then, the glass fiber is evenly dispersed on the resin paste film, and a layer of film with resin paste is covered on it—roll compaction to form a sheet molding compound a...Read more -

What is SMC?

SMC is a molding compound used in the dry-process manufacturing of unsaturated polyester fiberglass products. The material is highly resistant to heat, insulation, and corrosion and is widely used in transportation vehicles, construction, electronics/electrical, and other industries. Composition ...Read more