Glass fiber is an inorganic non-metallic material with excellent performance. Wear resistance is poor. It is made of pyrophyllite, quartz sand, limestone, dolomite, borosite and borosite as raw materials through high-temperature melting, wire drawing, winding, weaving and other processes. The diameter of its monofilament is several microns to twenty microns, equivalent to 1/20-1/5 of a hair. Each bundle of fiber strands is composed of hundreds or even thousands of monofilaments. Glass fibers are usually used as reinforcing materials in composite materials, electrical insulating materials and thermal insulation materials, circuit substrates and other fields of the national economy.

Properties:

Melting point Glass is a kind of amorphous. It has no fixed melting point. It is generally believed that its softening point is 500~750℃, its boiling point is 1000℃, and its density is 2.4~2.76g/cm3

When glass fiber is used as a reinforcing material for reinforced plastics, the biggest feature is its high tensile strength. The tensile strength is 6.3~6.9 g/d in the standard state and 5.4~5.8 g/d in the wet state. Density 2.54g/cm3. Good heat resistance, no effect on strength when the temperature reaches 300 ℃. It has excellent electrical insulation, is a good electrical insulation material, and is also used for thermal insulation materials and fire shielding materials. Generally only corroded by concentrated alkali, hydrofluoric acid and concentrated phosphoric acid.

Main ingredients:

Its main components are silicon dioxide, aluminum oxide, calcium oxide, boron oxide, magnesium oxide, sodium oxide, etc. According to the alkali content in the glass, it can be divided into alkali-free glass fiber (sodium oxide 0%~2%, belongs to aluminum Borosilicate glass), medium alkali glass fiber (sodium oxide 8%~12%, belongs to boron-containing or boron-free soda lime silicate glass) and high alkali glass fiber (sodium oxide more than 13%, belongs to soda lime silicate glass).

Main feature:

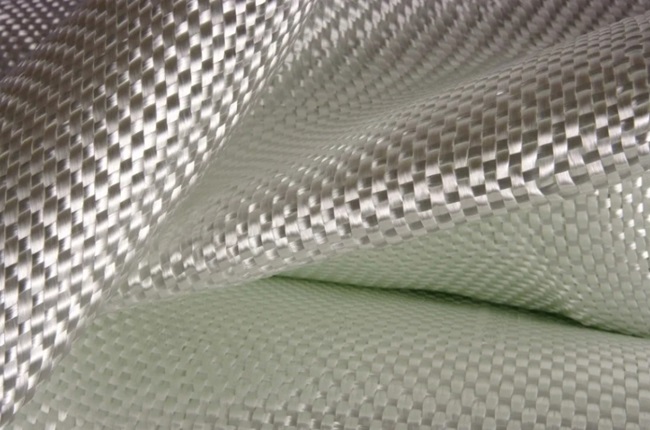

Raw material and its application: Compared with organic fiber, glass fiber has higher temperature resistance, non-combustibility, corrosion resistance, good heat insulation and sound insulation, high tensile strength and good electrical insulation. But it is brittle and has poor wear resistance. It is used to make reinforced plastics (see color picture) or reinforced rubber. As a reinforcing material, glass fiber has the following characteristics. These characteristics make the use of glass fiber far more extensive than other types of fibers. The development speed is also listed as follows:

(1) High tensile strength and small elongation (3%).

Fiberglass Cut Yarn

(2) High elastic coefficient and good rigidity.

(3) The amount of elongation within the elastic limit is large, and the tensile strength is high, so the absorption of impact energy is large.

(4) It is an inorganic fiber, which is non-flammable and has good chemical resistance.

(5) Low water absorption.

(6) Scale stability and heat resistance are good.

(7) It is well-processed and can be made into various products, such as strands, bundles, felts, and woven fabrics.

(8) Transparent through light.

(9) The development of a surface treatment agent with good adhesion to resin has been completed.

(10) The price is cheap.

(11) It is not easy to burn and can be melted into glass beads at high temperatures.

Material classification:

According to shape and length, glass fiber can be divided into continuous fiber, fixed-length fiber and glass wool. According to the glass composition, it can be divided into alkali-free, chemical-resistant, high alkali, medium alkali, high strength, high elastic modulus and alkali resistance ( anti-alkali) glass fiber, etc.

The main raw materials for producing glass fiber are: quartz sand, alumina and pyrophyllite, limestone, dolomite, boric acid, soda ash, mirabilite, fluorite, etc. The production methods are roughly divided into two categories: one is to make molten glass into fibers directly; the other is to first make molten glass into glass balls or rods with a diameter of 20 mm, and then heat and remelt in various ways to make glass balls or rods with a diameter of 3~3 mm. 80μm very fine fibers. The infinitely long fibers drawn by the mechanical drawing method of platinum alloy plates are called continuous glass fibers, commonly known as long fibers. Discontinuous fibers made by rollers or air flow are called fixed-length glass fibers, commonly known as short fibers.

Glass fibers are divided into different grades according to their composition, properties, and uses. According to the standard grade regulations (see table), E-grade glass fiber is widely used in electrical insulating materials; S-grade is a special fiber.

TechnoFRP provides fiberglass raw materials. If you have any needs, contact us!

Post time: Sep-21-2022