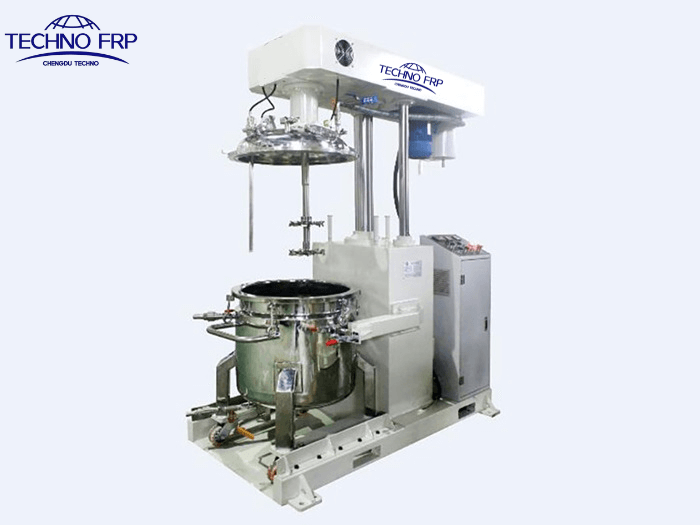

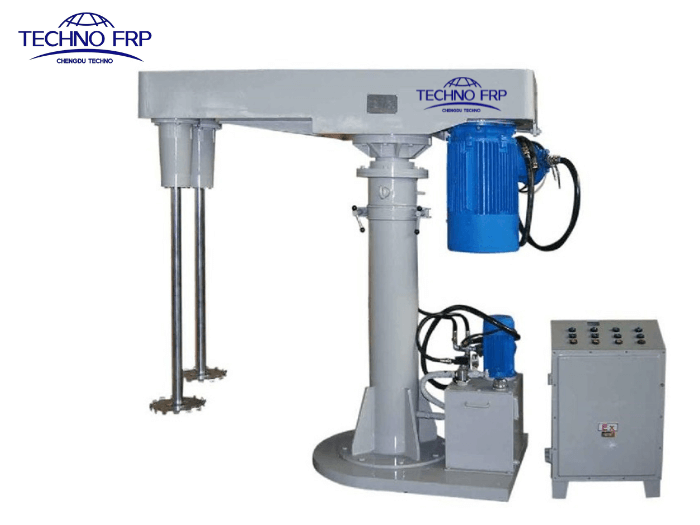

High Speed Disperser Machine

As a professional high-speed disperser manufacturer in China, technoFRP‘s high-speed dispersion mixers have the advantages of efficient dispersion and uniform mixing. It can quickly process materials with high viscosity and solid content while ensuring uniform dispersion and particle refinement. It has stable operation, low vibration during operation, and long service life, making it suitable for material handling needs in various industries. In addition. Our equipment also supports customized design and can adjust the specifications and speed of the dispersion disc according to different process requirements to improve production efficiency and quality.

Our high-speed dissolvers can independently complete the entire process of dispersion grinding, refinement, cooling, filtration, vacuum suction, and semi-automatic filling, greatly reducing labor intensity. The production time is 1/5 of the time traditional equipment consumes, shortening the processing time and facilitating cleaning. It can be operated under a vacuum without bubble generation or dust flying, greatly improving product quality.

High speed disperser working principle

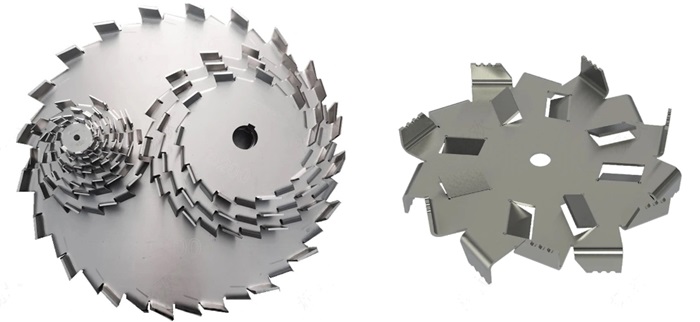

The serrated circular dispersion disc of the high shear disperser disperses at high speed in the container to complete the solid-liquid dispersion, wetting, depolymerization, and stabilization process. The slurry is in a rolling annular flow, generating a strong vortex. The particles on the surface of the slurry spirally descend to the bottom of the vortex. A turbulent zone is formed at 2.5-5mm from the edge of the dispersion disc. The slurry and particles are subjected to strong shear and impact. Two upper and lower beams are formed outside the area. The slurry is fully circulated and turned. The bottom of the dispersion disc of the disperser is in a laminar state. The slurry layers with different flow rates diffuse with each other to play a dispersing role.

Working characteristics:

The strong centrifugal force throws the material from the radial direction into the narrow, precise gap between the stator and rotor. At the same time, it is subjected to the combined forces of centrifugal extrusion, liquid layer friction, hydraulic impact, etc. The material is initially dispersed.

The high-speed rotating rotor of the disperser generates a linear velocity of at least 15m/s. The material is fully dispersed and crushed under strong hydraulic shear, liquid layer friction, tearing collision, etc., and is ejected at high speed through the stator slot.

The material of the high shear disperser is continuously ejected at high speed from the radial direction. It changes its flow direction under the material’s resistance and the container wall. At the same time, under the action of the upper and lower axial suction forces generated in the rotor area, two strong turbulent flows are formed. After several cycles, the material finally completes the dispersion process.

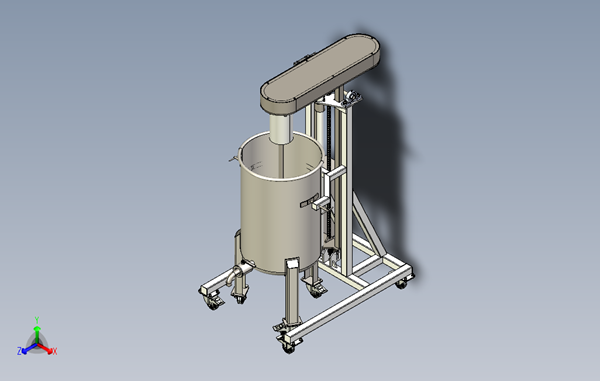

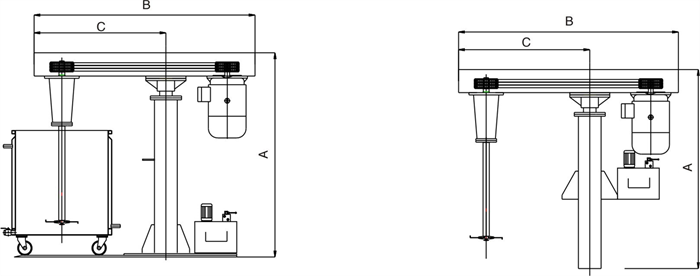

High speed disperser mixer drawing

High speed disperser blades

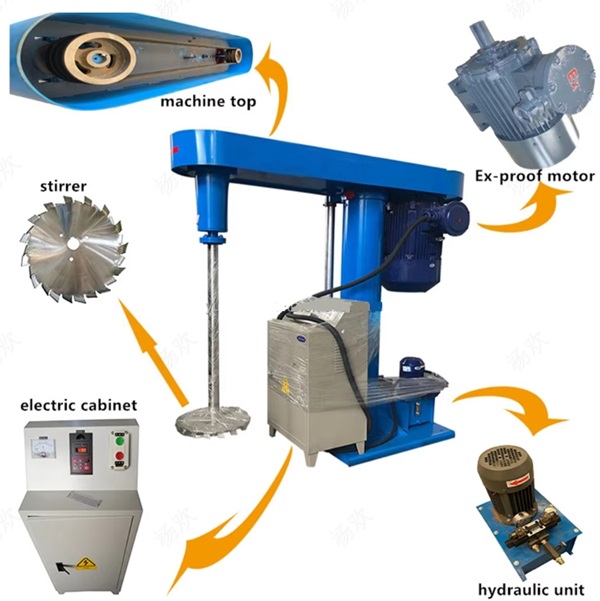

Structure of high-speed dissolver

It main consists of 5 parts:

• Mixing part: Shaft + Stirrer

• Frame part: Machine body

• Hydraulic unit: Hydraulic station + hydraulic motor

• Driving system: Main motor + Inverter + Belt + Pulley

• Electric control system: Control cabinet

Features of high speed disperser machine

1. The medium and high-speed stirring and dispersing can make the material dissolve quickly, making the particles smaller.

2. It adopts electromagnetic speed regulation, frequency conversion speed regulation, three-speed, and other specifications. It runs smoothly and powerfully and is suitable for various viscosities.

3. Hydraulic or pneumatic lifting, no leakage. Lifting and rotating freely, adapting to various positions.

4. The lifting structure uses a hydraulic cylinder as the actuator, and the lifting is smooth.

Advantages of high speed disperser

• The high-speed disperasion mixers (hydraulic lifting) has the functions of dispersing and stirring, which is suitable for mass production.

• Very little air is inhaled during stirring and dispersing, and the mixing and blending effect is excellent.

• The equipment adopts variable frequency drive step-less speed regulation, which can run continuously for a long time, smoothly, and with low noise.

• The stirring disc is easy to replace, and different dispersion discs can be replaced according to the production process.

• The integrated hydraulic station is environmentally friendly and leak-free, and it is an ideal grinder for multi-variety and multi-colour materials.

• Explosion-proof configuration, safe and reliable. Simple operation and maintenance, suitable for various materials.

Application of high-speed dissolver

High shear disperser is widely used in coating, ink, adhesive, chemical, food, medicine, plastic, and other industries to quickly disperse and mix solid particles, powder, or fiber in liquid. Specific applications include uniform mixing of pigments and additives, dispersion treatment of resins and emulsions, and production of pharmaceutical suspensions and food slurries. It is particularly suitable for processing high-viscosity materials and can greatly improve product dispersion effect and production efficiency.

Technical parameters of high speed disperser

| Model | Capacity(L) | Power(kw) | Speed(rpm) | Dispersion Dia(mm) | Lifting stroke(mm) | Hydraulic power(kw) |

| TechnoFRP-1.5 | ≤50 | 1.5 | 0-1450 | 150 | 600 | 0.55 |

| TechnoFRP-4 | ≤200 | 4 | 0-1450 | 200 | 800 | 0.55 |

| TechnoFRP-7.5 | ≤400 | 7.5 | 0-1450 | 230 | 900 | 0.55 |

| TechnoFRP-11 | ≤500 | 11 | 0-1450 | 250 | 900 | 0.55 |

| TechnoFRP-15 | ≤700 | 15 | 0-1450 | 280 | 900 | 0.55 |

| TechnoFRP-18.5 | ≤800 | 18.5 | 0-1450 | 300 | 1100 | 0.75 |

| TechnoFRP-22 | ≤1000 | 22 | 0-1450 | 350 | 1100 | 0.75 |

| TechnoFRP-30 | ≤1500 | 30 | 0-1450 | 400 | 1100 | 0.75 |

| TechnoFRP-37 | ≤2000 | 37 | 0-1450 | 400 | 1600 | 1.1 |

| TechnoFRP-45 | ≤2500 | 45 | 0-1450 | 450 | 1600 | 1.1 |

| TechnoFRP-55 | ≤3000 | 55 | 0-1450 | 500 | 1600 | 1.1 |

| TechnoFRP-75 | ≤4000 | 75 | 0-950 | 550 | 1800 | 2.2 |

| TechnoFRP-90 | ≤6000 | 90 | 0-950 | 600 | 1800 | 2.2 |

| TechnoFRP-110 | ≤8000 | 110 | 0-950 | 700 | 2100 | 3 |

| TechnoFRP-132 | ≤10000 | 132 | 0-950 | 800 | 2300 | 3 |