FRP Water Tank Panel Semi-automatic Drilling Machine

The semi-automatic drilling machine for FRP water tank panels combines the advantages of automation and manual operation and is efficient, flexible and precise. The equipment can automatically complete the drilling process while allowing the operator to manually load and adjust the plate position to meet the processing needs of FRP water tank panels of different specifications. Its multi-drill configuration and simple control system improve production efficiency and ensure the accuracy of drilling, which is suitable for small and medium-sized enterprises or small-batch production. In addition, the equipment has a simple structure, easy operation and easy maintenance, making it an ideal choice for FRP water tank panel manufacturing in various industries.

Structure of the semi-automatic drilling machine for FRP water tank panels

The structural design of the semi-automatic drilling machine for FRP water tank panels is relatively simple, but it can meet the production needs of precise drilling and partial automation. The following are the main structural components of the equipment:

1. Frame structure

• Machine base and bracket: The equipment’s basis is a sturdy metal frame that ensures stability during operation. The machine base can withstand the force during drilling while reducing vibration.

• Guide system: Horizontal or vertical guides are installed on the frame to support the smooth movement of the drilling head and the workbench. The guide rails are usually high-precision linear guides to ensure positioning accuracy.

2. Drill system

• Drilling unit: The drilling unit consists of a spindle and a drill bit. A motor drives the spindle to provide sufficient power and speed to complete the drilling operation.

• Multi-axis design (optional): Some semi-automatic drilling machines can be equipped with multiple drilling axes, allowing multiple holes to be drilled simultaneously to improve production efficiency. Each drilling axis can be controlled independently to meet the needs of different plates.

• Manual or automatic adjustment: The height and position of the drill bit are usually adjusted manually. Some models may be equipped with a simple automatic adjustment function to facilitate processing plates of different thicknesses and sizes.

3. Workbench

• Mobile workbench: The workbench is used to place and fix the FRP water tank plate, usually a manual or semi-automatic mobile platform. The operator can manually adjust the position of the workbench or control simple automatic movement through buttons.

• Clamping device: The workbench is equipped with a clamping system to firmly fix the FRP plate to prevent displacement during drilling and ensure the accuracy of the drilling position.

4. Positioning system

• Mechanical positioning device: Semi-automatic drilling machines are usually equipped with a mechanical positioning system, which helps the operator accurately position the FRP plate through positioning pins or limit blocks to ensure that each plate’s drilling position is consistent.

• Manual positioning adjustment: The operator needs to manually adjust the plate’s initial position, and the system helps the operator position it using simple auxiliary tools (such as a ruler or optical aiming).

5. Control system

• Manual control panel: Semi-automatic drilling machines usually have a simple control panel that allows the operator to control the start and stop of the drilling unit, speed adjustment and workbench movement. Compared with fully automatic equipment, the operator’s participation is higher.

• Limit switch: The equipment is equipped with a limit switch to ensure that the drilling unit automatically stops after reaching the specified depth to prevent over-drilling.

This structural design ensures that the FRP water tank panel semi-automatic drilling machine has a certain degree of automation while maintaining accuracy. It is suitable for small and medium-sized production lines and has the advantages of high flexibility and relatively low cost.

Features of FRP water tank panel semi-automatic drilling machine

The features of a semi-automatic drilling machine for FRP water tank plates are reflected in that some processes are completed automatically by the machine. In contrast, other processes still require manual intervention. Such a design can improve efficiency while maintaining flexibility and low cost. The following are the main features of semi-automatic operation:

1. Automated drilling

The drilling process is completed automatically: Once the plate is fixed and positioned, the machine automatically performs the drilling operation, including the rotation, feed and drilling depth control of the drill bit. The operator only needs to start the drilling program, reducing the tediousness of manual drilling.

2. Manual loading and positioning

Manual loading of plates: The operator needs to manually place the FRP water tank plate on the workbench and perform preliminary fixing and positioning. The equipment may have simple auxiliary positioning devices, such as limit blocks or mechanical guides, to help the operator quickly complete the positioning.

3. Manual adjustment of drill position

Adjustable drill bit or workbench: Depending on the plate specifications or the hole position, the operator needs to manually adjust the height or position of the drill bit or move the workbench to the corresponding position. This manual adjustment provides greater flexibility for the equipment, which can adapt to different sizes of water tank plates or customized drilling requirements.

4. Partially automated control

Simple automated control system: Semi-automatic equipment is equipped with basic automated control, such as drill start and stop, feed speed adjustment, etc., which are usually operated by buttons or switches. The operator can simplify the operation process through the control panel, but it does not rely entirely on programmed control like fully automatic equipment.

5. Lower degree of automation, retaining flexibility

• Adaptability: Because manual intervention is required, semi-automatic equipment is more flexible in dealing with different specifications and types of plate processing. Compared with fully automatic equipment, semi-automatic equipment is easier to adjust according to different production tasks.

• Combination of manual control and automation: Operators can adjust each processing step according to production needs, retaining control over the production process to a certain extent and reducing the complex operation and debugging time that may occur in fully automatic equipment.

6. Flexibility and cost-effectiveness

Suitable for small and medium-sized enterprises: Semi-automatic equipment’s flexibility and lower cost make it suitable for small and medium-sized enterprises or production environments with small order volumes and diverse specifications. Compared with fully automatic equipment, semi-automatic operation is easier to maintain and does not require complex operating skills.

The operating characteristics of the FRP panel semi-automatic drilling machine combine automatic drilling with manual intervention. The automated part improves the efficiency and consistency of drilling, while the manual part enhances the equipment’s flexibility and adaptability. Such a design can reduce equipment costs and operational complexity while maintaining efficiency and is an ideal choice for small and medium-sized production lines.

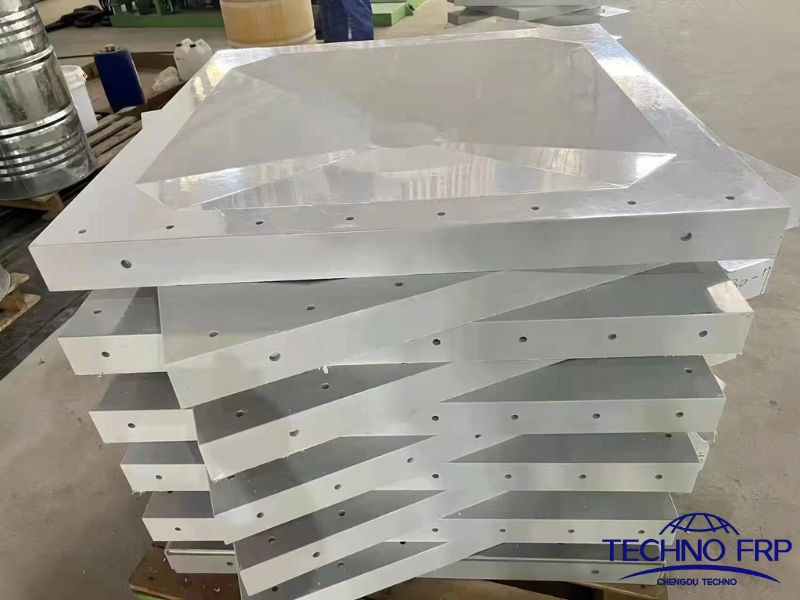

Application of FRP panels semi-automatic drilling machine

FRP water tank panels are widely used in water supply and storage systems, such as building water supply equipment, domestic water tanks, fire water tanks, etc. These water tank panels require precise drilling during assembly for connection and fixation. The semi-automatic drilling machine can process water tank panels quickly and efficiently by combining automatic drilling and manual operation. It is widely used in industries that require FRP water tank panel processing, especially in small and medium-sized production environments or when mass production requirements are not high.