FRP Rebar Pultrusion Machine

FRP rebar pultrusion machine is the equipment used to produce FRP rebars. These bars are widely used in construction, bridges, roads and other projects, mainly replacing traditional steel bars. FRP rebars have the advantages of lightweight, corrosion resistance, high tensile strength, etc., and are an environmentally friendly and durable material.

Techno‘s FRP rebar production lines have been perfected over the past 10 years and have now reached the pinnacle of their products. The FRP rebars produced by our equipment have enhanced strength properties (breaking strength, fracture strength and tensile strength) and are appreciated by professional construction companies around the world.

We manufacture 2 different FRP rebar production lines:

CT4 with 4 simultaneous outputs

CT6 with 6 simultaneous outputs

Our FRP rebar pultrusion machine is designed to be reliable and efficient! All our developments and innovations are patented, guaranteeing the efficiency of your investment. In addition, to ensure the reliability of all our line modules, we only use components that have passed our rigorous testing and performance evaluations.

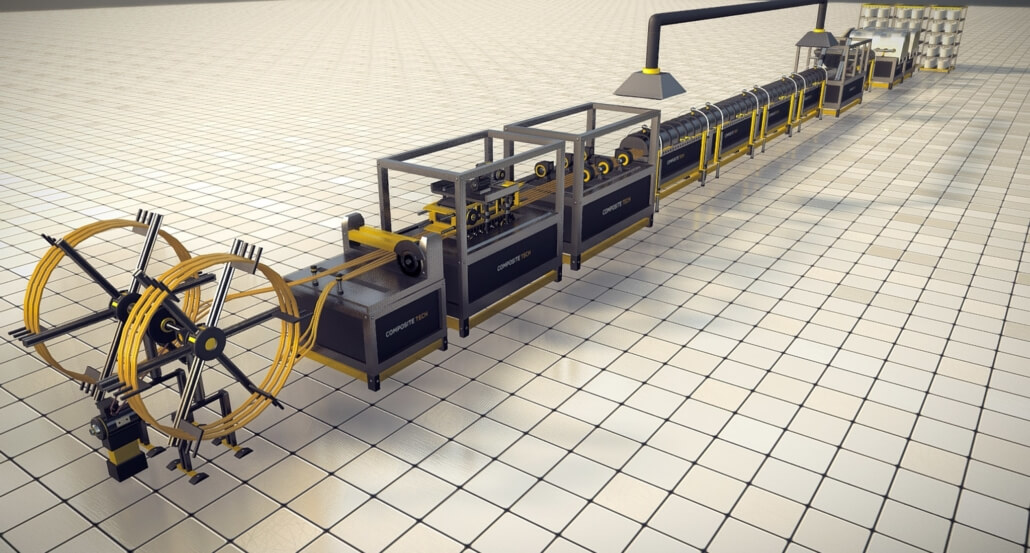

Structure of FRP rebar pultrusion machine

This FRP rebar machine mainly consists of a yarn frame, dipping tank, winding, oven, traction machine, cutting saw and stacking device.

1. Yarn frame: Placing the yarn group, assembled split type, easy to in stall.

2. Dipping tank: Welded with stainless steel material, with an internal pressure roller to make the roving fully impregnated in the resin.

3. Winding device: It adopts gear transmission to drive the thread roller to rotate around the product and wind the thread. Adopting the frequency conversion speed control method, the speed can be adjusted steplessly, and it can produce 4 pieces of FRP rebars at the same time.

4. Oven: It is heated by a heater and controlled by an intelligent temperature controller. The heating box adopts a split

structure, which can be easily opened to clean up dripping resin, and the interior is filled with heat insulation materials.

5. Automatic tracking cutting saw: The GFRP rebars on the production line can be cut to length online according to specific requirements.

6. Product stacking rack: After cutting, the GFRP rebars are stacked and taken away by production personnel for stacking.

Features of FRP rebar pultrusion machine

• Designed for small cross-sections and hollow profiles, it operates smoothly and reliably and has a significant energy-saving effect.

• Ultra-high molecular weight polyethene chain guide rails are wear-resistant and protect products from contamination.

• It adopts a wear-resistant polyurethane pressing block and double-row chain traction.

• The integral retractable traction frame is easy to adjust and effectively ensures that the traction force is in the same direction as the product.

• It uses a Japanese Mitsubishi frequency converter and programmable controller (PLC) to realize functions such as automatic cutting, unloading, and traction speed regulation.

Types of TechnoFRP’s FRP rebar machine

| Type | Produce Diameter Range |

| 2 lines FRP rebar machine | DN4-40mm |

| 4 lines FRP rebar machine | DN4-32mm |

| 5 lines FRP rebar machine | DN4-26mm |

Applications of FRP rebar pultrusion machine

FRP rebar making machines, especially pultrusion machines, are widely used in various industries that require high-strength and corrosion-resistant materials, especially in construction, infrastructure, marine engineering and other fields.

These machines impregnate glass fibers with resin and then pultrut them through molds to produce lightweight, high-strength, corrosion-resistant FRP rebars, which can be used to replace traditional steel bars in bridges, roads, tunnels, subway stations and other engineering projects. In these projects, the corrosion resistance, lightweight, and durability of FRP rebars have significantly improved the durability of the structure. They are especially suitable for use in humid, acid-alkali environments, reducing maintenance costs and potential safety hazards in long-term use.

In addition, as FRP pultrusion machines improve in accuracy and production efficiency, they are gradually being applied to special environments such as ocean platforms, chemical plants, and sewage treatment plants, providing more reliable material solutions.

FRP rebar machine parameter

| Forming mold frame installation length | 900mm |

| Forming mold frame width | 550 mm |

| Forming mold frame height adjustment | 80mm |

| Heating section (220V) | 6 |

| Traction block | Customized according to product shape |

| Effective traction length | 4000 mm |

| Traction speed | 0.1~1m/min |

| Traction force | 100KN |

| Traction rubber block length | 300 mm |

| Traction method | Flat crawler type |

| Cutting power | 1.5KW |

| Dust suction power | 1.5KW |

| Maximum cutting section size | 500X85mm |

| Saw blade speed | 2850r/min |

| Saw blade diameter | φ400/φ50 |

| Cutting method | Automatic/manual |

| Tracking cutting stroke | 700 mm |

| Overall dimensions | 25mx1.3mx1.7m |