FRP Rebar Machine

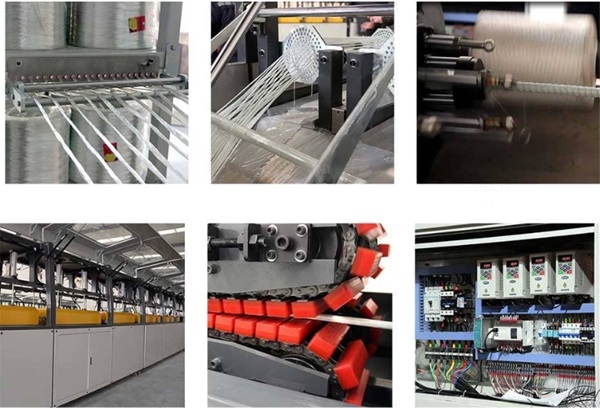

FRP pultrusion is one of the new FRP production processes, forming easily. The main materials are fiberglass and resin. It is a continuous process for manufacturing products with a constant cross-section, such as rod stock, structural shapes, beams, channels, pipe, tubing, fishing rods, etc.

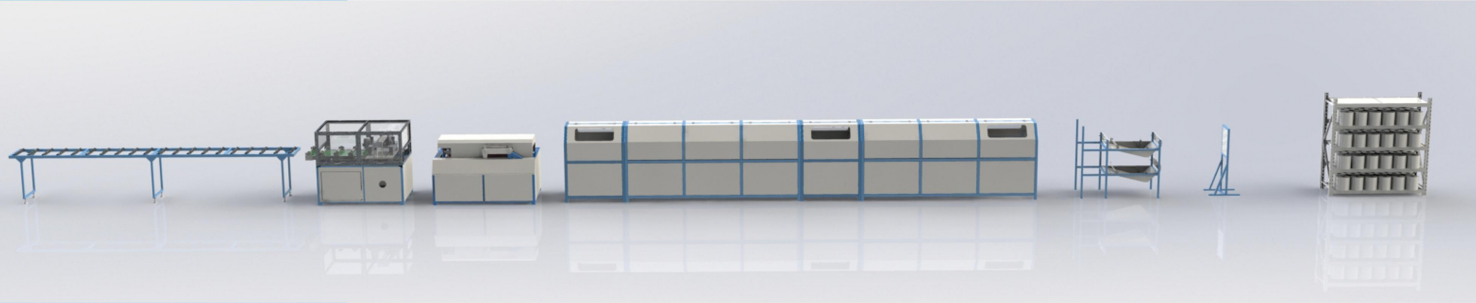

The FRP rebar machine is mainly used to produce FRP Rebar of various specifications. TechnoFRP is a professional pultrusion machine manufacturer in China That provides high-quality FRP/GPR rebar production lines.

| Model | Rebar-1 | Rebar-2 | Rebar-5 |

| Total power | 30kw | 30kw | 35kw |

| No.of winding head | 1 | 2 | 5 |

| Winding diameter | Max.32mm | Max.40mm | Max.40mm |

| Clamping length | 1300mm | 1200mm | 1200mm |

| Traction force | Max.40kn | Max.40kn | Max.40kn |

| Clamping width | 215mm | 500mm | 500mm |

| Traction speed | 0.1-1.5m/min | 0.1-1.0m/min | 0.3-4.0m/min |

Write your message here and send it to us