FRP Profile Pultrusion Machine

FRP profile pultrusion machine is a kind of equipment specially used for producing glass fiber reinforced plastic (FRP) profiles. It combines glass fiber with resin (such as unsaturated polyester or epoxy resin) through a continuous pultrusion process and solidifies and forms FRP profiles with various cross-sectional shapes. These profiles are widely used in construction, the chemical industry, electric power, transportation and marine engineering due to their lightweight, high strength and corrosion resistance.

TechnoFRP is a professional FRP pultrusion machine manufacturer in China, providing not only high-quality fiberglass pultrusion machines but also a whole line of FRP profile production solutions, perfectly solving your production problems.

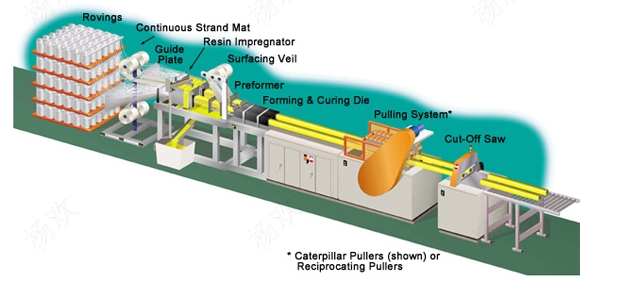

Composition of FRP profile pultrusion machine

FRP pultrusion equipment consists of three parts: mechanical, hydraulic and electrical.

• The mechanical part consists of a heating rack, a dipping tank, a rack and two clamping gantries.

• The hydraulic part consists of two independent hydraulic systems, which are respectively composed of clamping cylinders, thrust cylinders, oil pumps, motors, solenoid valves, speed-regulating valves, overflow valves, oil filters, and oil tanks.

• The electrical part includes heating controllers, temperature controllers, control boxes, etc.

• Auxiliary equipment includes electromagnetic speed-regulating mixers, pneumatic automatic cutting machines, electric carpet cutting machines, etc., constituting the entire FRP profile production line.

Working principle of FRP pultrusion machine

The working principle of FRP hydraulic pultrusion equipment is to heat and shape the FRP raw materials in the mold, and then use two clamping and pulling gantries to alternately operate to continuously pull them out to obtain the required various FRP profiles.

Features of fiberglass pultrusion machine

1. The whole machine adopts PLC control, and the traction control adopts automatic and manual control systems.

2. The temperature control is a high-precision, dual-display instrument with six zones that can be controlled separately.

3. The cutting saw adopts variable frequency speed regulation for fixed-length cutting.

4. The qualitative table template is electrically adjusted up and down.

5. The hydraulic traction device has a variety of working modes to choose from, with step-less speed regulation.

6. The product adopts the upper clamping method.

7. Equipped with a hydraulic oil cooling system and fault alarm system.

Advantages of FRP profile pultrusion machine

• Strong traction, stable and reliable operation.

• Easy to adjust the production process.

• Excellent dual hydraulic system.

• Electrical and hydraulic components adopt well-known brands with high sensitivity and low failure rates to ensure equipment quality.

• Precise debugging structure and stable operation speed.

FRP pultrusion machine specifications

| Conventional dimensions | length 9000mm*width 1200mm*height 1500mm |

| Traction force (t) | 10-30 adjustable |

| Clamping force (t) | ≤5-30 adjustable |

| Traction speed (mm/min) | 50-1500 |

| Traction reciprocating stroke (mm) | ≥600 |

| Clamping stroke (mm) | ≥100 |

| Mold stand length (mm) | 900 |

| Mold clamping mechanism | screw clamping |

| Oil tank cooling water requirements | temperature 0-15℃ & flow not less than 100 Liter/hour |

| Automatic cutting gas source requirements | Applicable gas pressure 0.4-0.8MPa |

| Total power demand of the factory area | 10-12KVA, 380V voltage |

| Installation length of the production line | nearly 30,000mm |

| Heating zone | The heating zone adopts contactor heating, ensuring that the temperature control fluctuation range is ±5℃ and the temperature control range is 0-300℃. The heating temperature zone can be adjusted arbitrarily. Each zone of 3-6 can control the heating power of 6KW per zone. |

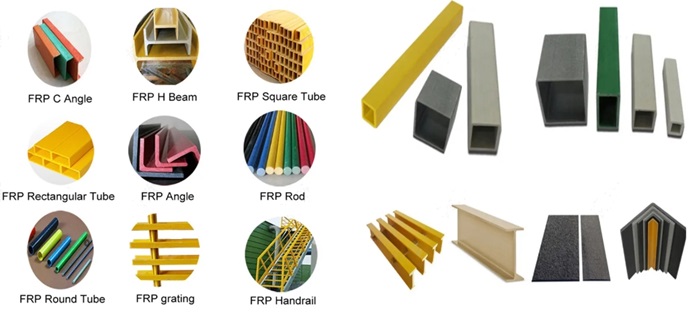

Application of fiberglass pultrusion machine:

1. Fiberglass tube

2. Fiberglass rod

3. Fiberglass flat strip/board

4. Fiberglass structural profiles

5. Fiberglass sheet pile

6. More custom profiles