FRP Grating Machine

Equipment parameters

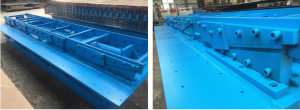

1. Mould base

Material: Made of 140-channel, Q235A-14mm steel plate welding;

Size: 1300mm * 3800mm * 55mm.

Processing: welding molding,milling machine precision milling through the upper panel,straightness and levelness reach 0.1mm/m.

Color: Iron Gray/surface treatment according to customers requirement.

2. Hydraulic lift system

Material: Q235A-25mm steel, 40Cr steel.

Insist of: Around slider 8 (40Cr),layering 16,trabecular 4, beam 2,the slider 2 (40Cr),outside diameter is ¢125,inside diameter is ¢100,cylinder 2 pieces.

Processing: 1) bolts links,slide machined from CNC milling machines made precision ≥0.02mm,grinding,deburring after quenching,which greatly improves the mechanical properties and wear resistance.Cylinder seals are made of imported high quality oil seals,practical and long life.

Color:Iron Gray/surface treatment according to customers requirement.

3. Ejection system

Material:100 * 70 * 5 of I-beam material is 65Mn, ¢6.5 thimble material is SKD61, Q235A thimble flake.

Insist of:Several I-beam,several 65Mn thimble,several thimble flake.

Process:

1) After the I-beam by CNC cutting machine cutting by milling on CNC milling / lower ends of the plane, at the ends of welding sealing;

2)After sealing I-beam through CNC drilling machine drilling thimble perforations, each 11 holes; 3)The thimble flake, beam bolted together;

3)Descaling, deburring paint treatment;

4) Color: Iron Gray / surface treatment according to customers requirement.