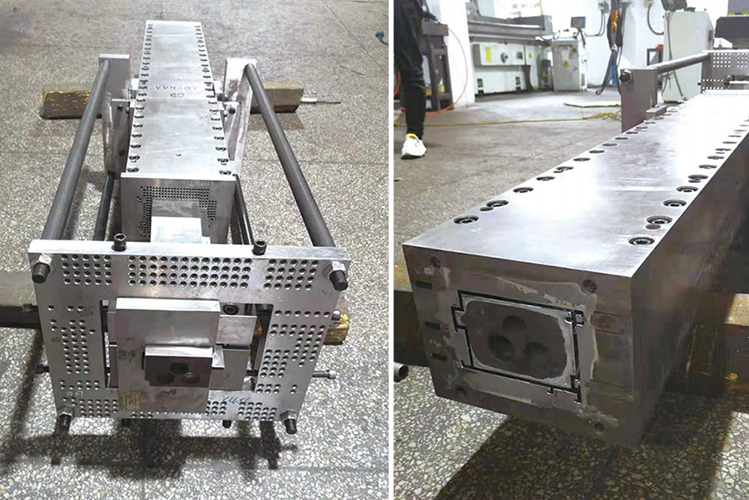

Customized Pultrusion Mold

An FRP pultrusion die is usually used to manufacture FRP pultrusion products such as pipes, profiles, etc. It is made of high-temperature and corrosion-resistant materials to ensure that it can withstand high temperatures and pressure during the extrusion process.

FRP pultrusion mould mainly produces FRP profiles such as pipes, beams, frames, etc. The die is fixed on the FRP pultrusion machine and forms FRP profiles through the roving and resin pultrusion process.

The mould adopts Cr12Mov, 40Cr or P20 materials with the advantages of high rigidity and good toughness. It is customized and only sales along with pultrusion machine.

The mould adopts Cr12Mov, 40Cr or P20 materials with the advantages of high rigidity and good toughness. It is customized and only sales along with pultrusion machine.

Advantages of pultrusion machine dies

1. High precision: FRP pultrusion moulds use advanced processing technology to ensure the dimensional accuracy and surface quality of the products.

2. High efficiency: The pultrusion molding process has the characteristics of continuous production, and rapid mold replacement and adjustment can improve production efficiency.

3. Corrosion resistance: FRP pultrusion molds are highly resistant to corrosion and are suitable for producing products with strong chemical corrosion.

4. Long life: The selection of mold materials and surface treatment can increase the service life of the mold and reduce production costs.

Applications of FRP pultrusion machine mould

• Construction field: FRP pultrusion molds can be used to produce FRP doors and windows, guardrails, stair handrails and other products.

• Chemical field: FRP pultrusion dies can be used to produce FRP pipes, storage tanks, cooling towers and other products.

• Power field: FRP pultrusion molds can be used to produce FRP cable trays, insulators and other products.

• Transportation field: FRP pultrusion dies can be used to produce FRP auto parts, ship parts and other products.

Parameter of FRP pultrusion machine dies

| mould material | chrome thickness | roughness | Flatness |

| S45C, P20, 40Cr, Cr12MoV | 0.03-0.05mm | Ra0.03 | 0.04mm/M |

| We also sopport customized sizes. | |||