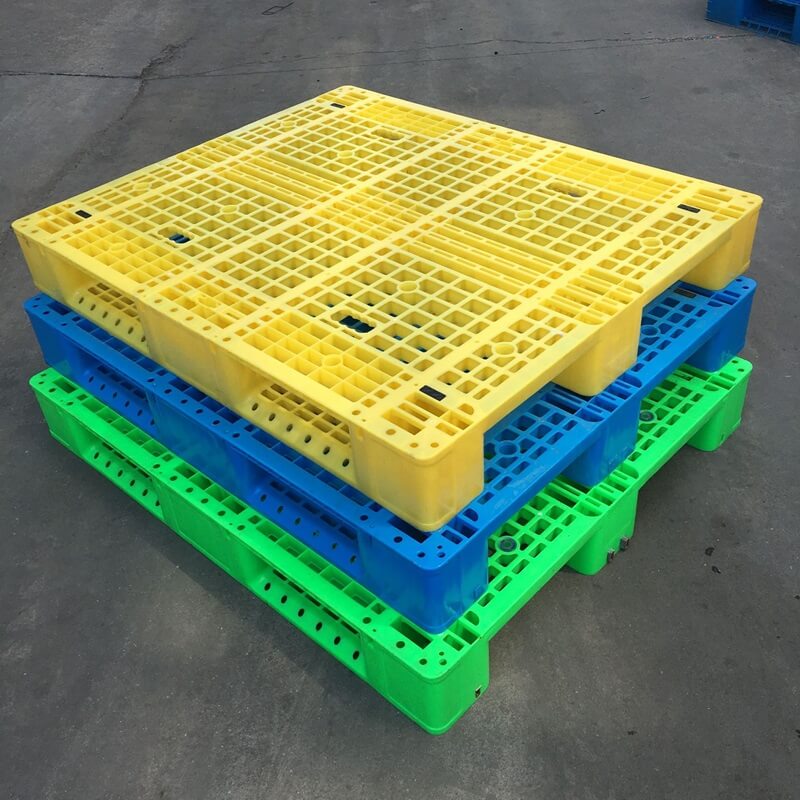

HDPE LDPE PP

Plastic Pallet Production Line

Our advanced plastic pallet production line is designed to transform waste plastics like HDPE, LDPE, and PP into durable plastic pallets, offering an energy-saving and environmentally friendly solution for your manufacturing needs.

Why Choose Our Solution?

1. Eco-Friendly & Sustainable

• Recycles waste plastics, reducing environmental impact.

• Energy-saving production process.

2. Cost-Effective

• Lower equipment costs compared to traditional injection or blow molding machines.

• Reduced labor requirements with a high degree of automation.

3. Versatile Production

• Suitable for producing various types of plastic or fiberglass products.

• Customizable solutions to meet your specific production needs.

Whether you're looking to expand your pallet production capabilities or enter the market with an environmentally friendly approach, TechnoFRP's compressed pallet production line ensures efficiency, reliability, and affordability.

Contact us today to learn how our solutions can help your business grow while staying green!

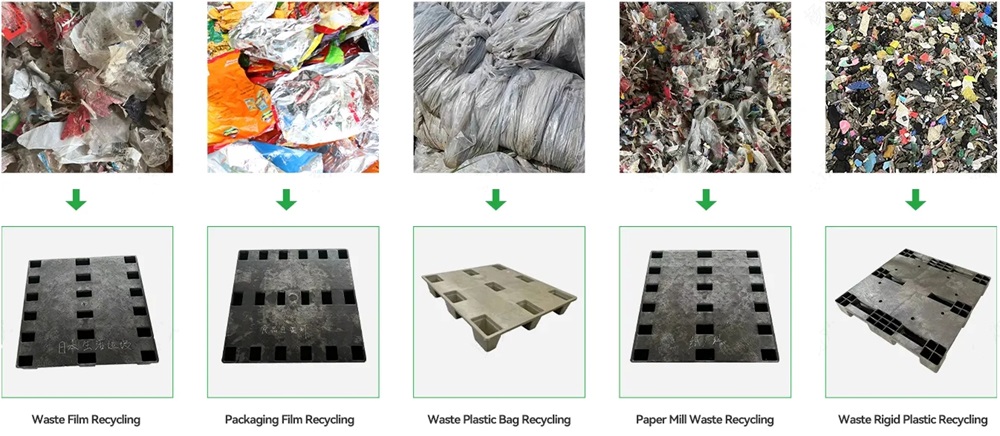

Products that Can be Made From Raw Materials

| Material | Plastics such as PS, PP, LDPE, PVC, HDPE, PET, and most waste plastics | Composite materials, raw materials containing glass fibers |

| Products | Plastic pallets, plastic flower pots, engine guards, bumpers, luggage racks, building formwork shells, etc. | FRP molded products, high-voltage electrical appliance housings, automobile covers, electric meter boxes, sinks, etc. |

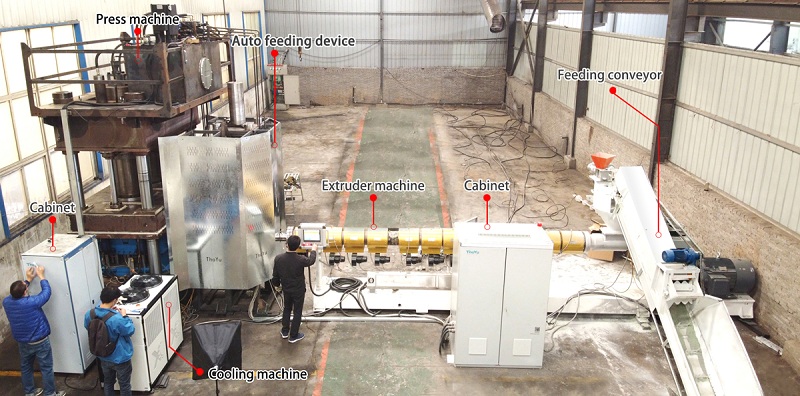

Compressed Plastic Pallet Production Line

The complete set of HDPE LDPE PP plastic pallet production line equipment includes a plastic extruder, heating equipment, plastic pallet molding press, mould, cooling system and take-out device.

Plastic Pallet Production Line Equipment List

HDPE LDPE PP Plastic Pallet Production Process

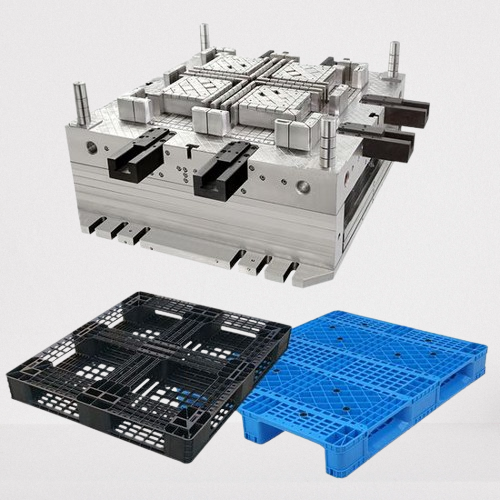

The plastic enters the plastic extruder through the feeding system. Thermoplastic sheets (such as HDPE, PP, etc.) are extruded. The prefabricated sheets (such as HDPE or PP) are heated to a softening temperature of 100°C-250°C by an electric heating plate or infrared heater to ensure that the material is evenly heated. Then, the softened sheet is placed between the molds. The plastic pallet molding machine applies high pressure of 10-50 MPa to make the sheet fit the mould shape. The mold is usually made of high-strength steel or aluminum alloy and is designed with the pallet's reinforcement ribs and structural features to ensure the finished product's precise shape. After the pressing, the pallet is hardened and shaped in the mold by natural or water cooling/air cooling. Then, the de-mould and the finished product are obtained.

This process is a compression molding process with very low requirements for raw materials and their impurities. It is suitable for a wide variety of raw materials, and does not require cleaning and filtering or granulation. It only needs to sort the recycled waste plastic from the large metal particles. After sorting, the waste metal can be recycled. Other plastics can also be made into products directly. Therefore, compression molding can reduce energy consumption, does not discharge wastewater and impurities, and is energy-saving and environmentally friendly.

After the finished product is demoulded, the tray needs to be trimmed to remove excess materials, and the dimensional accuracy, surface quality and mechanical properties are tested to ensure quality. The entire hot pressing process is efficient and has a high utilization rate of raw materials. The scraps can be recycled and reused, which reduces production costs.

Advantages of Plastic Pallet Production Line

1. Cost advantage

• Low raw material cost: The price of waste plastic is much lower than that of virgin plastic, which reduces production costs and increases profit margins.

• High waste utilization rate: Through crushing, cleaning, granulation and other steps, the scraps and unqualified products generated during the production process are directly recycled and reused, further saving costs.

2. Production advantage

• Strong compatibility: The HDPE LDPE PP plastic pallet molding line is compatible with a variety of waste plastic types (such as packaging bags, waste containers, etc.). Adjust the formula to meet the performance requirements of different pallets.

• Stable performance of finished products: Pallets made of recycled plastics still have good strength, durability and anti-ageing properties through reasonable formula and process control and are suitable for logistics, warehousing and other multi-scenario applications.

• Diversified design: The production line can produce pallets of various specifications, structures and uses by replacing molds and adjusting processes to meet the needs of different customers.

3. Environmental advantages

• Resource recycling: Recycling and reusing waste plastics (such as HDPE, PP, etc.) reduces dependence on virgin plastics and reduces resource consumption.

• Reducing environmental pollution: Recycling waste plastics reduces the pollution problems caused by landfills and incineration, which helps develop a circular economy.

• Reduced carbon emissions: Compared with the production of virgin plastic pallets, the use of recycled plastics significantly reduces the carbon footprint, helping companies achieve green production goals.