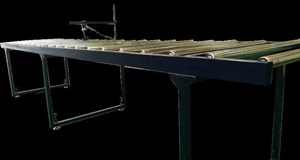

CFRP Pultrusion Machine

TechnoFRP has designed an FRP pultrusion machine production line to produce fibre-reinforced profiles such as angle steel, square steel, I-beam, U-channel, trench cover, ladder rungs, etc. To help you achieve high production, we recommend different equipment models according to the profile's cross-sectional size.

| Central Height of machinery | 1000mm |

| Total Power | ~15kw |

| Operating air pressure | 0.4-0.6MPa |

| Air consumption | ≈20L/min |

| No.of bobbins | 120 bobbins/unit |

| Tension regulation | Group control or individual control |

| Length of the shaping platform | 900mm |

| Width of the shaping platform | 550mm |

| Traction speed | 0.1-20m/min |

| Traction force | 60KN |

| Rolling inner diameter | 1500-2240mm(optional) |

| Rolling speed | 0.1-1.5m/min(optional) |

Write your message here and send it to us