BMC Mixer

The BMC mixer developed and produced by our company is a kind of efficient batch production equipment developed by us based on the BMC production process combined with many years of production experience. It is production equipment for unsaturated polyester resin and short-cut fiber-reinforced bulk moulding compound (i.e. BMC batch).

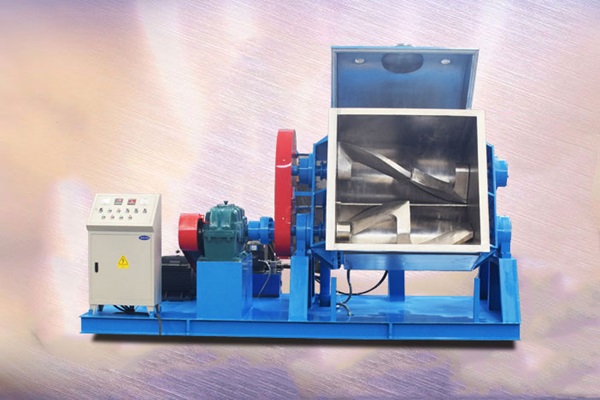

The BMC mixer is a kind of equipment for bulk molding compounds that introduces the resin paste made by the various components such as resin fillers, pigments, release agents, curing agents, etc., which are fully dispersed after high-speed rotation and are fully kneaded with short-cut glass fibers so that the resin paste fully penetrates the glass fibers. TechnoFRP‘s BMC kneading machine has automatic cylinder turning, hydraulic lifting of the machine cover and a water cooling system. This equipment is suitable for producing various bulk molding compounds with complex shapes, good appearance, low shrinkage and generally high strength.

Key technical features of TechnoFRP’s BMC mixer

High shear force: Strong stirring and shearing action ensure that materials such as glass fibre and resin are fully mixed.

Controllable temperature and pressure: Adjusting the kneading machine’s temperature and pressure helps ensure that the material properties meet the processing requirements.

Uniformity: Mechanical stirring ensures the mixture’s uniform dispersion and guarantees the final product’s quality.

The role of the mixer in BMC production

BMC mixer mainly produces unsaturated polyester resin (BMC, Bulk Molding Compound) mixture. BMC is a reinforced thermosetting plastic composite material that is widely used in electronics, electrical, automotive, construction, home appliances, and other fields. The role of the kneading machine in BMC production is mainly reflected in the following aspects:

♣ Mixed material preparation: The kneading machine is used to mix materials evenly, such as resin, glass fibre, filler, additives, etc., to ensure that the mixture has uniform dispersion and stability.

♣ Improve material properties: The mixer’s high shear force and uniform mixing process can improve the mechanical properties of BMC, such as tensile strength, flexural strength and heat resistance.

♣ Processing controllability: The BMC kneading machine’s temperature, pressure and shear force can be adjusted according to different materials and application requirements to produce BMC materials that meet specific application requirements.

♣ Efficient production: BMC kneading machines usually have efficient production capacity and can produce composite materials continuously and in large quantities, which is suitable for industrial production.

Working principle of BMC mixer

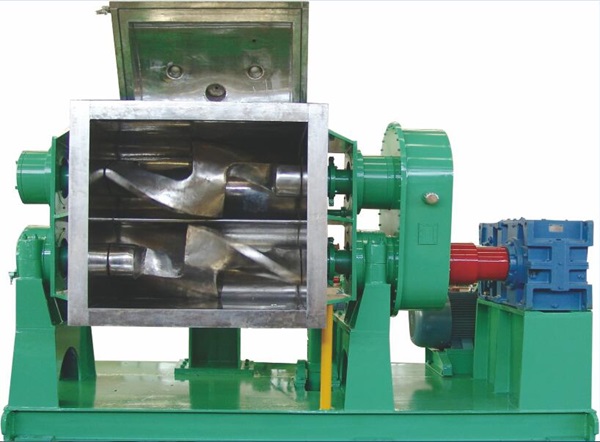

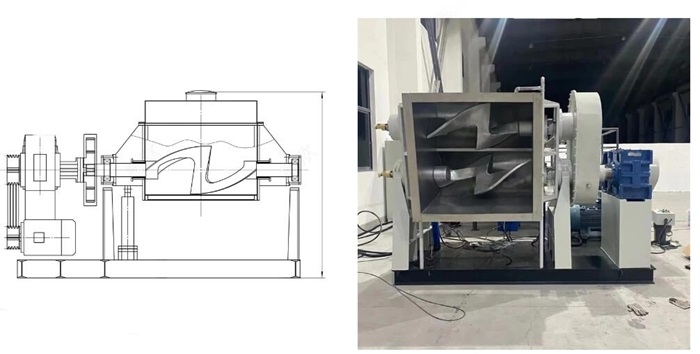

The core working principle of the BMC mixer is to rely on the rotational motion of twin screws or twin blades to perform kneading. The twin screws or blades exert shear force and extrusion force on the materials through different rotation directions and speeds so that they are evenly mixed and produce plastic fluidity in a short time. During the process, the mechanical shear force will evenly distribute the solid fillers, such as resin and glass fibre, together to obtain a uniform BMC mixture.

Structure of BMC mixer machine:

Including kneading/mixing system, machine base, hydraulic system, transmission system, electric control system, heating system (optional), cooling system (optional), vacuum system (optional)

—- Discharge: Tilting discharging

Screw extruding discharging

Ball valve/bottom plate ( manual, electrical, pneumatic)

—- Heating: electric heating, hot water heating, hot oil heating, steam heating

—- Cooling: Z blades water cooling, mixing chamber with a jacket for cooling.

—- Vacuum system: water-ring vacuum pump and buffer tank.

Advantages of TechnoFRP’s BMC mixer

BMC mixers are usually equipped with a temperature control system to ensure that the temperature during kneading is within a range suitable for resin chemical reactions and material processing. Proper temperature control can accelerate the mixing of materials while avoiding overheating that causes premature curing of materials.

During the kneading process, the BMC kneader will apply a certain amount of pressure to the raw materials, increase the shear force, fully mix the resin and other ingredients, and help the uniform distribution of glass fiber. The pressure of the kneading machine can be adjusted to suit different formulations and processing requirements.

TechnoFRP’s BMC mixer has high mixing efficiency. Fast powder eating and self-friction heating (unique cylinder design structure, large rotating diameter of the stirring shaft, corresponding cylinder widening, large rotating angle of the stirring shaft, and better shear force). Complementary to this, the quality of the products produced by this equipment, under the premise of the same formula and the same raw materials, has better dispersion uniformity, no particles or even agglomeration, high tensile strength and good fluidity.

The weight of the equipment is about 20%-30% heavier than that of the same brand. For example, our 2000L kneading machine has a machine weight of 25 metric tons. The material is thick; the high viscosity and hardness glue has good stability and a low maintenance rate.

Application of BMC mixer

BMC mixer is mainly used in automobile, electrical and electronic, home appliances, construction, transportation and medical industries. The BMC materials it produces have excellent properties such as high strength, heat resistance, flame retardancy and insulation. They are widely used in automotive lamps, engine parts, electrical switches, insulators, home appliance housings, building water pipes, door and window frames, train window frames, medical equipment housings and other products to meet the needs of various industries for high-performance composite materials.

Technical parameters of BMC mixers

| specification | 5L | 10L | 100L | 300L | 500L | 1000L | 1500L | 2000L | 3000L | |||

| Effective volume (L) | 5 | 10 | 100 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | |||

| Feeding amount (L) | 3.5 | 7 | 70 | 210 | 350 | 700 | 1100 | 1400 | 2100 | |||

| Main motor power (Kw) | 1.1-1.5 | 4-7.5 | 7.5-18.5 | 15-30 | 18.5-45 | 22-55 | 37-75 | 45-110 | ||||

| Screw motor power (Kw) | NO | 3-4 | 3-4 | 4-5.5 | 5.5-7.5 | 7.5-11 | 11-15 | |||||

| Dischargethe way | High temperature | Manually turn cylinder | Hydraulic cylinder | |||||||||

| Other type | Manually turn cylinder | Hydraulic cylinder | Hydraulic turn cylinder, screw discharge, the next material | |||||||||

| Mixing speed (r/min) | 33/23 | 35/22 | 37/21 | 35/25 | 30/16 | |||||||

| Heating the way | High temperature | no | electricity | |||||||||

| Other type | Electricity/steam | |||||||||||

| Electric heating power (Kw) | HT | 6-10 | 8-10 | 12-15 | 30-35 | 35-45 | 60-80 | 90-110 | 110-140 | 160-190 | ||

| OTHER | 1.8 | 1.8 | 4.2 | 12 | 18 | 24 | 36 | 36-54 | 54-72 | |||

| Steam pressure (Mpa) | 0.3 | |||||||||||

| Vacuum type vacuum | -0.090Mpa | |||||||||||

| Pressure type pressure (MPa) | 0.45 | 0.35 | ||||||||||

| Dimension (mm) | ordinary | L | 1100 | 1100 | 1600 | 2150 | 2550 | 2750 | 3030 | 3060 | ||

| W | 410 | 410 | 610 | 850 | 1000 | 1200 | 1850 | 2250 | ||||

| H | 510 | 510 | 1360 | 1300 | 1550 | 1800 | 1850 | 2070 | ||||

| vacuum | L | 1100 | 1100 | 1600 | 2150 | 2550 | 2750 | 3030 | 3100 | |||

| W | 1000 | 1000 | 610 | 1250 | 1320 | 1600 | 2150 | 2350 | ||||

| H | 520 | 520 | 1360 | 1400 | 1550 | 1800 | 1850 | 2070 | ||||

| Weight (kg) | 210~300 | 250~340 | 1100~1250 | 2000~2200 | 2800~3000 | 4200~4500 | 5200~5500 | 6400~6800 | 9000~9500 | |||

| Table parameters for reference only, according to customer requirements can be designed (a variety of volume, speed and special requirements) dedicated models | ||||||||||||

TechnoFRP is a professional BMC mixer manufacturer, providing one-stop BMC product molding services, including BMC raw materials, BMC mixers, BMC product molding hydraulic presses and their molds. If you have any needs, please contact us.