BMC Manhole Cover

BMC is often called an unsaturated polyester bulk molding compound. Its main raw materials are GF (chopped glass fiber), UP (unsaturated polyester resin), MD (filler) and various additives that are fully mixed into a bulk prepreg. BMC manhole covers are formed by using a bulk molding compound with a steel frame and high-temperature molding by a BMC manhole cover molding machine.

| Model NO. | BS-500 | Shape | Square, Round, etc |

| Certification | ISO, CE | Color | Red/ Green /Black/ Gray /Yellow |

| Weight | 20kg | Loading | A15/ 5t |

| Metal Type | Steel | Features | Anti Corrosive, Easy Assemblied, Heavy Duty |

| Solar Cell Type | BMC | Application | Pedestrian Areas, Family Land, Parked Cars |

| Specification | 500x500x40mm | Production Capacity | 10000/Month |

| Working Temperature | -40ºC- 200ºC | Trademark | TechnoFRP |

BMC manhole covers are generally used in non-motorized vehicle lanes and green belts. Our composite manhole covers have a very strong anti-theft performance. Even if there are steel bars inside, the cost of removing them is much higher than the value of the steel bars themselves. As a professional BMC manhole cover factory, TechnoFRP‘s BMC manhole cover is an excellent lightweight manhole cover product. Its lightweight design, high strength, corrosion resistance, anti-slip, and other characteristics make it widely popular in the market and an indispensable part of urban construction and maintenance.

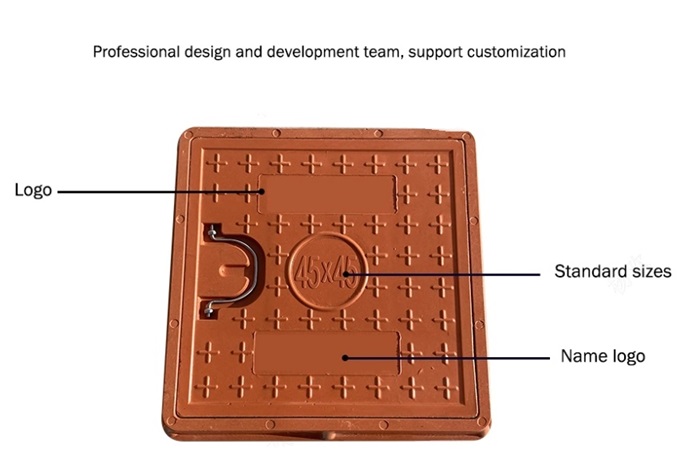

Drawing of BMC manhole cover

| Item NO. | Material | Loading Class | O | D | F | h | H | Weight |

| BS-500 | BMC | A15 | 450mmx450mm | 500mmx500mm | 600mmx600mm | 40mm | 60mm | 20.0Kg |

Features of BMC manhole covers

BMC manhole covers have a variety of advantages that make them widely used in municipal, industrial and civil facilities.

1. High strength and pressure resistance

BMC manhole covers are specially formulated and hot-pressed for extremely high strength and withstand large loads and pressures. It is suitable for various heavy-load occasions and can meet the use requirements in high-load environments such as urban roads and industrial areas.

2. Lightweight and convenient

Compared with traditional cast iron manhole covers, BMC manhole covers are much lighter, usually one-third to one-half of cast iron manhole covers. This makes installation and maintenance more convenient, reduces construction time and labor costs, and does not require the use of heavy equipment for installation and removal.

3. Corrosion resistance

BMC materials have extremely strong corrosion resistance and can resist erosion by acids, alkalis, salts and other chemicals. They are very suitable for use in humid, salt spray or highly corrosive environments, such as chemical plants, coastal areas, etc., and have a long service life.

4. Anti-theft

BMC manhole covers do not contain metal components, so they have no recycling value, reducing the risk of manhole covers being stolen. This is useful in public facilities and communities with high anti-theft requirements and safer than cast iron manhole covers.

5. Good insulation

BMC materials have good electrical insulation properties and are non-conductive. They are suitable for cable wells, telecommunication wells and other places that require electrical safety. They can prevent power leakage or equipment short circuits and ensure safe use.

6. Weather resistance

BMC manhole covers have excellent weather resistance, can withstand extreme climatic conditions such as high temperature, low temperature, rain and snow, and are not easy to age or deform. It can maintain stable performance under different climatic conditions to ensure long-term use.

7. Environmental protection

BMC materials are environmentally friendly and do not contain harmful ingredients, and the production process will not cause environmental pollution. After the manhole cover is abandoned, it will not cause secondary pollution to the environment, which meets modern environmental protection standards and sustainable development requirements.

8. Aesthetics and customization

The color and appearance of the BMC manhole cover can be customized according to needs and match the surrounding environment. Unlike the single black color of traditional cast iron manhole covers, BMC manhole covers can be made into a variety of colors, such as gray, green, and blue, which enhances the overall landscape aesthetics. In addition, the surface texture can also be designed to increase the anti-slip function.

9. Safety

The material properties of BMC manhole covers make them non-flammable and non-conductive, making them particularly suitable for use in places with high safety requirements, such as power equipment and chemical companies. Its anti-slip surface design can also effectively prevent pedestrians or vehicles from slipping on rainy days, improving safety.

10. Wear resistance and impact resistance

The surface of BMC manhole covers has good wear resistance and impact resistance, is not easily damaged or worn under high load and frequent use, and can maintain the integrity and performance of the manhole cover for a long time.

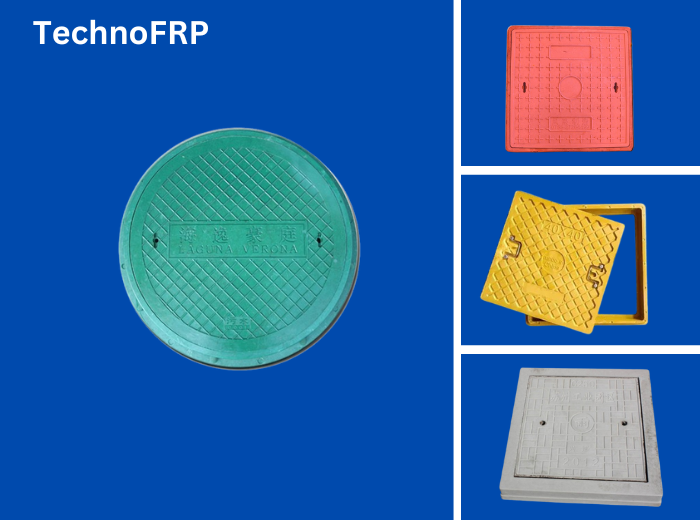

Shapes of BMC manhole covers

The shapes and specifications of BMC manhole covers vary according to different application scenarios. Common shapes include:

• Round manhole covers: This is the most common manhole cover shape, mainly used in municipal and transportation fields. The round design is conducive to the close combination of the manhole cover and the manhole to prevent tilting.

• Square manhole covers: Commonly found in sidewalks, residential areas and other occasions, the square manhole cover has a simple design and is convenient for smooth integration with the surrounding ground.

Specifications of BMC manhole covers

BMC manhole covers for different occasions have different specifications, generally including light, medium and heavy manhole covers used to withstand different load requirements. Light manhole covers are suitable for occasions such as sidewalks or parks, medium manhole covers are suitable for parking lots or residential areas, and heavy manhole covers are often used on roads with heavy traffic or industrial areas.

| FRAME SIZE(MM) | COVER SIZE(MM) | CLEAN OPENING(MM) | BEAR WEIGHT | CLASS |

| 300*300 | 250*250 | 200*200 | 2T | A15 |

| 300*300 | 250*250 | 200*200 | 5T | A15 |

| 400*400 | 300*300 | 250*250 | 2T | A15 |

| 400*400 | 350*350 | 250*250 | 5T | A15 |

| 450*450 | 350*350 | 350*350 | 5T | A15 |

| 500*500 | 400*400 | 350*350 | 2T | A15 |

| 500*500 | 400*400 | 350*350 | 5T | A15 |

| 550*550 | 450*450 | 400*400 | 5T | A15 |

| 600*600 | 500*500 | 450*450 | 5T | A15 |

| 600*600 | 500*500 | 450*450 | 10T | A15 |

| 700*700 | 600*600 | 550*550 | 5T | A15 |

| 700*700 | 600*600 | 550*500 | 20T | A15 |

| 800*800 | 700*700 | 650*650 | 5T | A15 |

| 900*900 | 800*800 | 750*750 | 5T | A15 |

| 1100*1100 | 1000*1000 | 950*950 | 2T | A15 |

Colors of BMC manhole cover

Application scenarios of BMC manhole cover

Due to its excellent performance, BMC manhole covers are widely used in the following fields:

› Municipal roads: BMC manhole covers are often used as manhole covers for urban drainage systems and sewage systems and can withstand the daily load of vehicles and pedestrians.

› Residential and commercial areas: BMC manhole covers are widely used in low-load areas such as sidewalks, parking lots and residential areas. They are practical and customizable in appearance and can blend into the surrounding environment.

› Industrial areas: In industrial environments such as chemical plants and sewage treatment plants, BMC manhole covers can be used stably for a long time due to their corrosion resistance and high-temperature resistance.

› Telecommunications and power facilities: In places such as telecommunications equipment wells and cable wells that require insulation and corrosion resistance, BMC manhole covers are widely used due to their insulation and corrosion resistance.

› Ports and airports: In areas such as ports and airports that need to withstand heavy vehicle loads, BMC manhole covers also have excellent performance, and weather resistance and corrosion resistance ensure a long service life.