BMC Kneading Machine | BMC Kneader

BMC agglomeration kneader is a machine that can quickly and evenly mix viscous materials through the strong shearing, extrusion, and stirring effects generated by a pair of rotating blades cooperating. It is a high-performance, ideal equipment for mixing, kneading, crushing, and polymerizing high-viscosity or ultra-high-viscosity materials.

TechnoFRP‘s BMC kneading machine is made of stainless steel or carbon steel for the parts in contact with the materials, which can ensure the purity and quality of the products. The machine adopts “Z” type double-paddle stirring, making the materials react quickly and mix evenly. This series of products is divided into three categories: ordinary type, pressure type, and vacuum type. There are two heating methods, electric and steam, and water cooling, from which to choose. The discharging methods include hydraulic cylinder dumping type, manual dumping type, ball valve discharging type, and screw extrusion type.

BMC polymer material kneading machine is suitable for kneading, mixing, and stirring various viscous materials and is widely used in chemical, plastic, pharmaceutical, rubber, adhesive, food, and other industries.

Working principle of BMC kneading machine:

Our BMC kneader is a horizontal double-shaft type with a Z-shaped stirring paddle and a W-shaped cylinder. When working, the motor is driven to the reducer through a V-belt, and then the two stirring paddles are driven to work through the gears. The Z-shaped stirring paddle is made by unfolding the Archimedean spiral line, and the two paddles are arranged horizontally and parallel, rotating in opposite directions with different speeds. The W-shaped cylinder consists of two semi-cylindrical cavities with a transverse material dividing ridge in the middle. Electric heating pipes can be installed in the interlayer, and electricity, steam, and cooling water can be passed through for heating and cooling operations.

When working, the propeller blades of the stirring paddle make the material axially extruded and radially sheared, both high-speed and low-speed extrusion. Extrusion and separation movements are used so that the material is fully kneaded and blended, mixed evenly, and the chemical reaction of the material is accelerated.

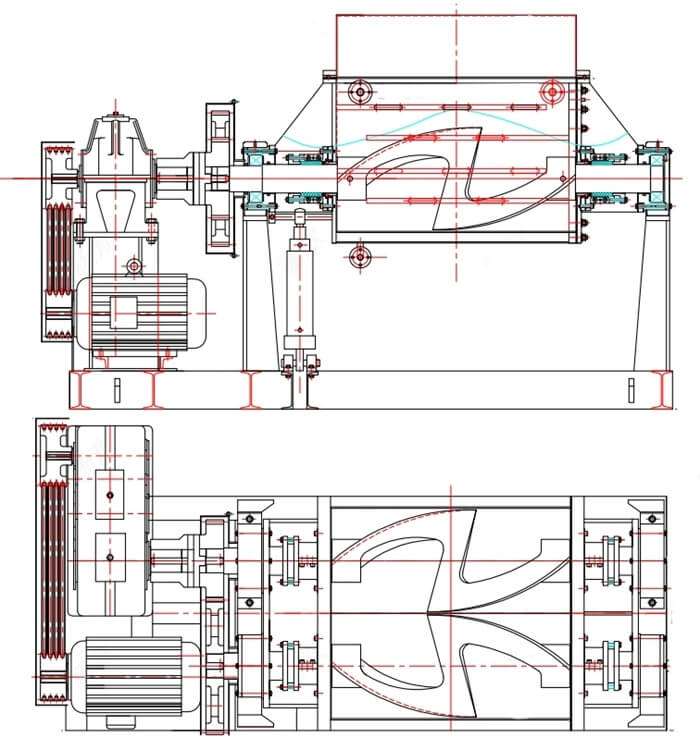

Drawing of BMC kneader

Features of TechnoFRP’s BMC kneading machine

1. In real-time, PLC controls and records relevant data, such as temperature, time, viscosity, etc., during production.

2. To ensure product quality, the barrel, blades, and material contact parts are made of stainless steel.

3. The BMC kneading machine can be used for high-viscosity pastes or plastic solids with poor fluidity of about 5000Pa·s. The jacket can be heated or cooled with heat transfer oil or water.

4. According to special needs, it can be designed to operate under vacuum conditions.

5. The speed difference between the two shafts is 7.52r/min, the material changes continuously, the mixing is rapid, and the unit volume transfer area is larger.

6. The ratio of direct stirring volume to the total volume of the cylinder is preferably 52%. The pages of the stirring paddle, the inner wall of the mixing cylinder, the inner plate of the wall panel and the cylinder cover are all made of stainless steel. It has the characteristics of wear resistance, corrosion resistance and ensuring material quality.

7. The aspect ratio of the stirring paddle and the spiral angle and working surface pressure angle of each section are locked. The eddy current and kneading performance of the material are very good.

8. The integrated chassis is adopted, which is convenient for installation and debugging.

Technical parameters of BMC kneader

| Model | Total Volume(L) | Working Volume(L) | Motor Power (KW) | Discharge way | Heating mode |

| NH - 50 | 50 | 30 | 2.2 ~ 4 | Hydraulic tilt | Steam/hot water |

| NH - 100 | 100 | 60 | 3 ~ 5.5 | Hydraulic tilt | Steam/hot water |

| NH - 200 | 200 | 120 | 5.5 ~ 7.5 | Hydraulic tilt | Steam/hot water |

| NH - 300 | 300 | 180 | 7.5 ~ 11 | Hydraulic tilt/bottom drop | Steam/hot water |

| NH - 500 | 500 | 300 | 11 ~ 18.5 | Hydraulic tilt/bottom drop | Steam/hot water |

| NH - 1000 | 1000 | 600 | 18.5 ~ 30 | Hydraulic tilt/bottom drop | Steam/hot water |

| NH - 1500 | 1500 | 900 | 22~37 | Hydraulic tilt/bottom drop | Steam/hot water |

| NH - 2000 | 2000 | 1200 | 37~55 | Hydraulic tilt/bottom drop | Steam/hot water |

| NH - 3000 | 3000 | 1800 | 55~90 | Hydraulic tilt/bottom drop | Steam/hot water |

| NH - 4000 | 4000 | 2400 | 75~110 | Hydraulic tilt/bottom drop | Steam/hot water |

| NH - 5000 | 5000 | 3000 | 90~132 | Hydraulic tilt/bottom drop | Steam/hot wate |

| NH - 6000 | 6000 | 3600 | 132~160 | Hydraulic tilt/bottom drop | Steam/hot water |

Application of BMC kneading machine

BMC kneading machine is ideal for kneading, mixing, vulcanizing and polymerizing high-viscosity, elastic-plastic materials. Through the efficient processing of BMC kneaders, composite materials can meet the special needs of various industries in terms of performance and durability.

• Electronic and electrical industry: BMC materials have good insulation and flame retardancy and are often used to manufacture electrical switches, junction boxes, insulating seats, etc.

• Automotive industry: BMC materials are often used in automobile engine parts, lampshades, instrument panels, etc., due to their high strength, lightweight and heat resistance.

• Construction industry: BMC kneaded materials are used to manufacture various building components, such as manhole cover, water pipes, floor tiles, door and window frames, etc.