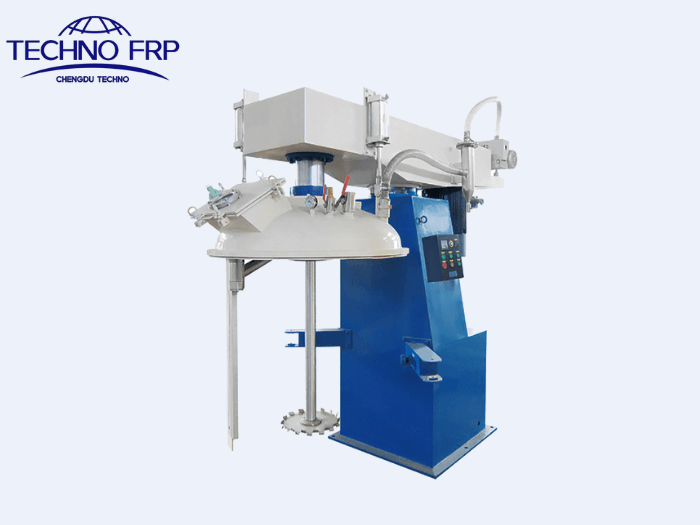

BMC High Speed Disperser

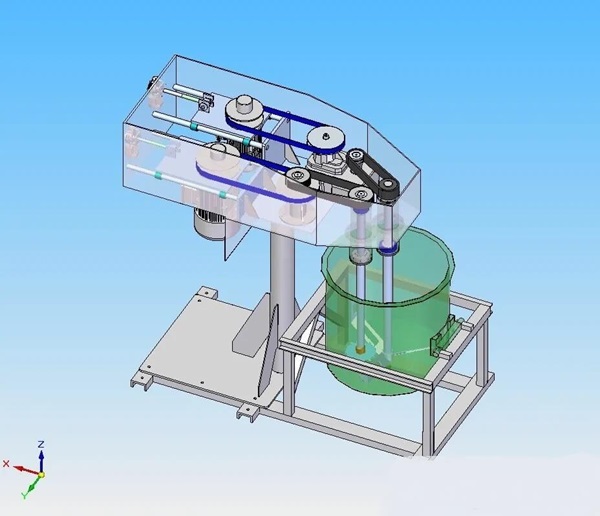

BMC High-speed dispersers quickly disperse and shear materials through high-speed rotating dispersion discs. They are widely used in adhesives, paints, coatings, chemicals, plastics and other industries. The equipment consists of five parts: a hydraulic system, a main drive, a stirring system, a guide mechanism, and an electric control box. Each part has a compact and reasonable structure. It is suitable for mass production.

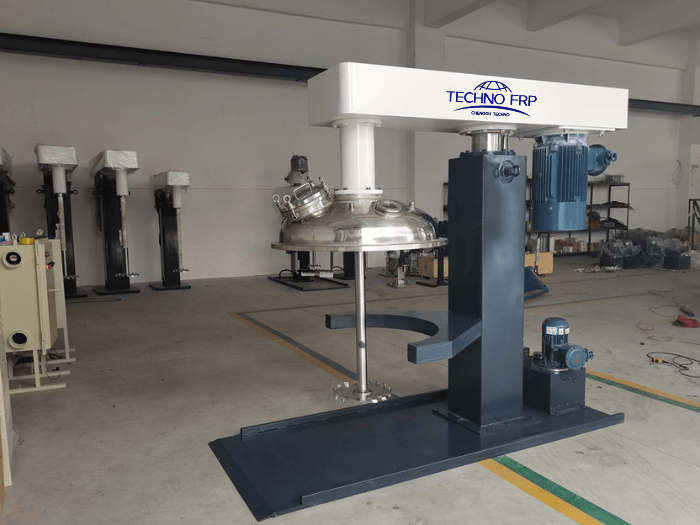

TechnoFRP is a professional high-speed disperser manufacturer in China. Our BMC high-speed disperser mixer has strong production continuity and can quickly disperse and dissolve materials. It has a good dispersion effect and high production efficiency and is suitable for dispersing and mixing materials of various viscosities. At the same time, it is safe and reliable, and easy to operate and maintain. It is the preferred equipment for mixing BMC raw material.

BMC high speed disperser mixing rules

Through the high-speed rotation dispersing disc, the materials will become in an annular form flow, resulting in a strong vortex flow, which descends to the bottom of the vortex in a spiral state. During the process, materials are dispersed, dissolved, mixed, and emulsified efficiently due to the strong shearing crash and friction among the particles.

Processed material: Various slurries with material viscosity below 25000 cps and solid content below 60%.

BMC high-speed disperser design

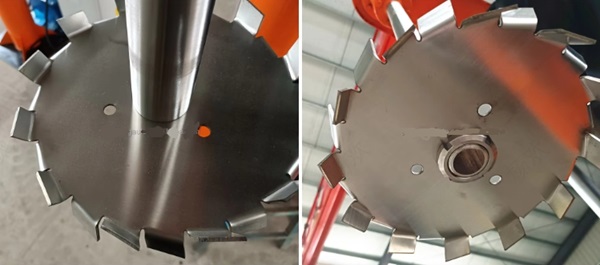

BMC high speed disperser blades

Structure of BMC high-speed dissolver

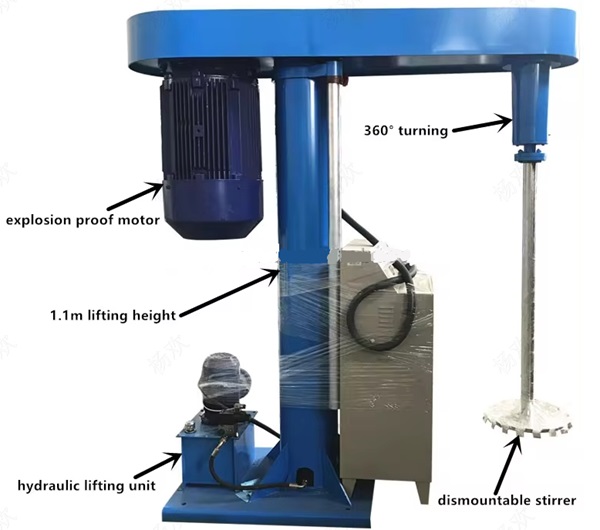

Features of BMC high-speed disperser

1. Adopt step-less speed regulation. There are various forms, such as electromagnetic speed regulation, frequency conversion speed regulation (water-based paint), and explosion-proof frequency conversion speed regulation (oil-based paint). The step-less speed regulation function can fully meet the different process requirements of each process, and different speeds can be selected according to different process stages.

2. It has multiple functions such as hydraulic lifting, 360-degree rotation, step-less speed regulation, etc. 2-4 containers can be configured simultaneously. The hydraulic lifting stroke of 1000㎜ and 360-degree rotation function can better meet the multi-purpose of one machine. It can be switched from one cylinder to another in a very short time. TechnoFRP‘s BMC disperser greatly improves work efficiency and reduces labor intensity.

3. The BMC high-speed disperser mixer forms a turbulent zone at 2.5-5mm on the edge of the dispersion disc. The slurry and particles are subjected to strong shear and impact to achieve the functions of rapid mixing, dissolution, dispersion, and refinement.

Advantages of BMC high speed disperser:

• Efficient dispersion: The high-speed rotation of the dispersion disc generates strong shear force, which can quickly mix solid particles and liquids evenly. It is especially suitable for processing materials with high viscosity and solid content.

• High power: The motor power of the equipment is large, and it can process BMC materials with high viscosity and fiber reinforcement characteristics.

• Good stability: The equipment has good mechanical stability when running at high speed, which reduces vibration and prolongs its service life.

• Wide application: BMC high-speed disperser machine is suitable for mass production and can be used in the manufacturing fields of fiberglass products, automotive parts, electrical products, etc.

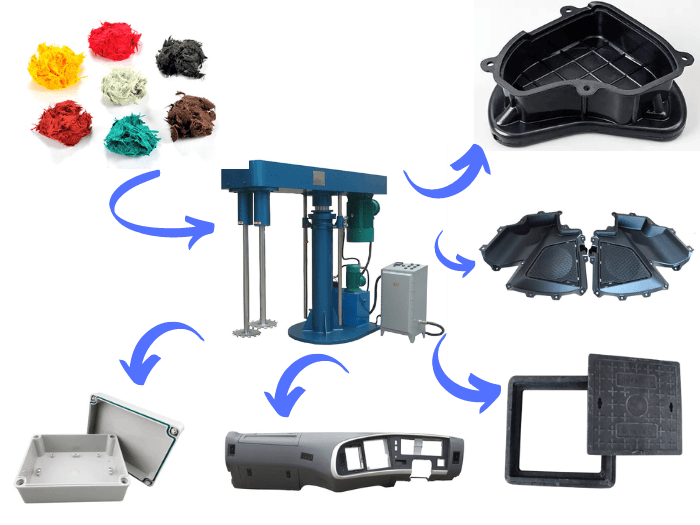

Application of BMC high speed disperser

BMC high-speed dispersion mixers are widely used in automobile manufacturing, electronic appliances, building materials and other industries. It is mainly used to process BMC (bulk molding compound) materials and can efficiently disperse components such as glass fiber, filler and resin to mix the materials evenly. Specific construction industry applications include automotive parts such as bumpers, headlight housings, electronic and electrical junction boxes, and heat-resistant and insulating parts. This type of disperser is particularly suitable for processing high-viscosity, fiber-reinforced materials.

Technical parameters of BMC high-speed disperser

| Model | TechnoFRP-1.5 | TechnoFRP-4 | TechnoFRP-7.5 | TechnoFRP-11 | TechnoFRP-15 | TechnoFRP-18.5 | TechnoFRP-22 | TechnoFRP-30 | TechnoFRP-37 | TechnoFRP-45 |

| Motor power (kw) | 1.5 | 4 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 |

| Speed | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm | 0-1450rpm |

| Disc dia(mm) | 120 | 200 | 230 | 250 | 280 | 300 | 350 | 400 | 400 | 450 |

| Production capacity(L/batch) | ≤60 | ≤200 | ≤400 | ≤500 | ≤700 | ≤800 | ≤1000 | ≤1500 | ≤2000 | ≤2000 |

| Hydraulic power(kw) | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 | 1.1 | 1.1 |

| Lifting(mm) | 600 | 900 | 900 | 900 | 900 | 1100 | 1100 | 1100 | 1600 | 1600 |

| Weight(kg) | 400 | 600 | 800 | 1000 | 1100 | 1300 | 1400 | 1500 | 1600 | 1900 |