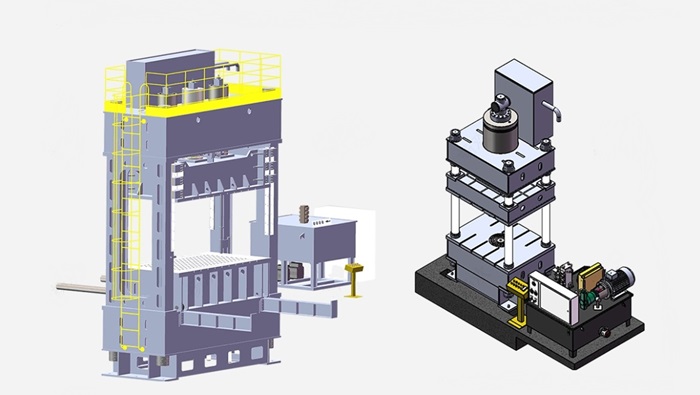

BMC Composite Manhole Cover Press Machinery

Composite manhole covers have the advantages of low price, lightweight, anti-theft, and reduced urban noise. In terms of corrosion resistance, BMC composite resin manhole covers are resistant to acid, alkali, salt corrosion, and rust. They are suitable for use in harsh environmental conditions from -50℃ to 150℃.

Our BMC composite manhole cover hydraulic press is suitable for the production of various types of resin manhole covers. Whether it is a round manhole cover, a square manhole cover, or other special shapes of manhole covers, it can easily complete the molding task. At the same time, it can also be customized according to customers’ special requirements to meet the personalized needs of different customers.

Structural features of BMC composite manhole cover press machinery

1. Body: The press body is welded with high-strength steel. The overall frame is strong and stable and can withstand huge working pressure without deformation. During the welding process, we strictly follow the advanced welding process standards to ensure that every weld is firm and reliable, providing a solid foundation for the long-term and stable operation of the equipment.

2. Hydraulic pump: Select high-quality hydraulic pumps with high pressure and stable flow.

3. Hydraulic cylinder: Use precision-machined hydraulic cylinders with good sealing and smooth piston movement of the hydraulic cylinder. It can accurately transmit pressure and ensure the accuracy of manhole cover forming.

4. Hydraulic valve: Equipped with an advanced hydraulic valve group, it can accurately control the flow direction, pressure, and flow of hydraulic oil. It has the advantages of fast response speed and high control accuracy. It can quickly adjust the working state of the equipment according to different work needs.

5. Oil pipes and joints: Use high-quality oil pipes and joints that are firmly connected and well-sealed and can withstand the impact of high-pressure hydraulic oil without damage or leakage.

BMC composite manhole cover production process

The compression molding of BMC manhole covers adds a certain amount of molding material (lump) into the preheated mold and solidifies it after pressurization and heating. The specific process is weighing → adding materials → closing the mold → filling the mold (lump flows under pressure and fills the entire mold) → solidification → (fully solidifying after maintaining it at the set pressure and temperature for a certain period of time) → opening the mold to take out the product → grinding burrs → finished product.

BMC compression molding process conditions

1. Molding pressure: 3.5-7MPa for ordinary products, 14MPa for products with high surface requirements.

2. Molding temperature: The mold temperature is generally 145±5℃, and the fixed mold temperature can be adjusted down 5-15℃ for demolding.

3. Mold closing speed: It is best to complete the mold closing within 50 seconds.

4. Curing time: The curing time for products with a wall thickness of 3mm is 3 minutes, the curing time for products with a wall thickness of 6mm is 4-6 minutes, and the curing time for products with a wall thickness of 12mm is 6-10 minutes.

Advantages of choosing technoFRP

TechnoFRP is a well-known hydraulic press supplier in China. We provide resin manhole cover-forming hydraulic presses of various specifications to meet the needs of different customers. We also have a professional after-sales service team to provide customers with timely and thoughtful technical support and maintenance services. We provide services such as equipment installation and commissioning, operator training, etc., to ensure customers can use the equipment smoothly.