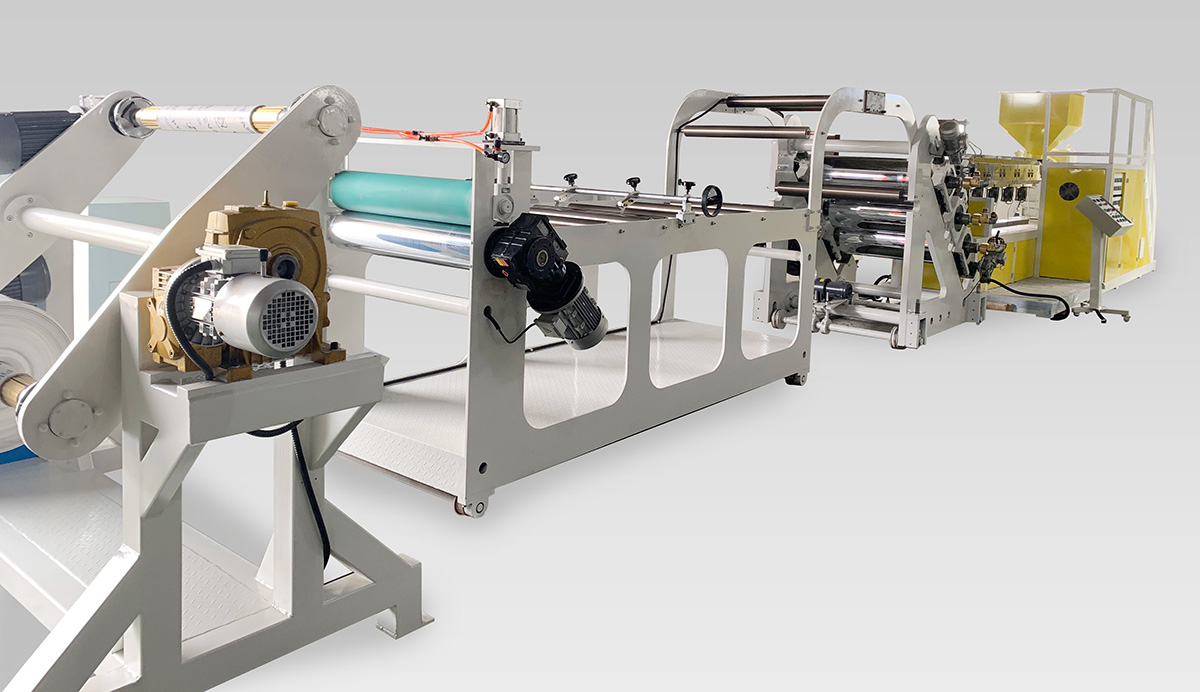

Automatic SMC Sheet Machine Production Line

Automatic SMC sheet machine production line is mainly used in the automotive, construction, electrical, home appliance, and transportation industries. These industries use SMC materials’ lightweight, high strength, corrosion resistance, and excellent insulation properties to manufacture body parts, exterior wall panels, electrical housings, home appliance housings, and public infrastructure products to meet large-scale, high-quality production needs.

As a professional SMC sheet machine manufacturer in China, TechnoFRP provides high-quality SMC sheet machines and complete SMC product solutions.

SMC Sheet Machine Automated Production Line:

1. Sheet structure: The whole machine is a two-part structure. The cutting area is one part, and the impregnation and winding areas are the other parts. The machine frame comprises 5.5mm*200mm and 5.5mm*100mm carbon steel square tubes.

2. The production speed of the SMC sheet machine is 1-20m/min. The speed is continuously adjustable, and the impregnation is good. When the film’s tensile strength is reached, the fastest production speed is 3 tons per hour. It is recommended that when the glass fiber content is higher than 30%, the production speed is 6-8m/min.

3. The total power of the SMC sheet machine is 8.85kw for a single knife and a single press and 13.45kw for a double knife and a double press. The working voltage is 380V.

4. The production width of the SMC sheet machine is 1000mm, 1200mm, or 1500 mm. This is the actual width measured after the upper and lower surface films of the SMC sheet are removed.

5. Glass fiber content and length of SMC sheet machine: The applicable range of glass fiber content is 10-60%. The glass fiber length can be adjusted as needed, including 12.5mm, 25mm, 37mm, 50mm, etc. It can also be mixed with long and short.

6. Conveying device: This machine uses a stainless steel double-chain mesh belt to convey PE film. The drive of the mesh belt adopts variable frequency speed control, which runs smoothly and has high-speed regulation accuracy. The supply of PE film is pneumatically controlled, the film tension is adjustable, and a flattening device is provided. Ensure that the film enters the paste area without wrinkles.

7. Paste scraping decoration: This machine uses a high-precision scraper and a bottom plate. The gap accuracy can reach 0.03mm, ensuring that the scraper evenly applies the resin paste to the PE film.

8. Glass fiber cutting device: This machine uses a spiral knife roller and an imported insulating ester rubber roller. Cutting is controlled by air pressure to ensure smooth operation. Improving the blade life and cutting quality is conducive to better dispersion of glass fiber, thereby improving the quality and performance of the product.

9. Impregnation method: staggered roller with mesh belt. The impregnation area is equipped with multiple pressurized cylinders or air bags to ensure good sheet impregnation. The mesh belt has an automatic error correction function.

10. Winding device: a roll-type and box-type winding, which can be used alternately. The box-type winding is controlled by frequency conversion speed regulation, the front and rear swing amplitude is adjustable, and the packaging cost is low.